The Stone Age Didn’t End Because We Ran Out of Stone.

By Barry Hudson

In this article, Barry Hudson, co-founder of Price Bee, discusses the pitfalls of relying on spreadsheets, like Microsoft Excel, Google Sheets – or even Lotus 123 (can you remember this?) to run a business in our industry, with input from Thomas Bergmans, senior vice president, Logistics of INFORM in Germany. – Ed.

Spreadsheets have been around since MTV was a big deal. And although they have their purpose, such as one-off analysis and process prototypes, the reliance on this type of technology if fraught with pitfalls, often brought about by operating in a false economy. To clarify, a driver of spreadsheet use is that spreadsheets are “free” and do not require you to clearly spell out the business objective.

Along with the current buzz around sustainability, net zero and social responsibility, comes the need around digital transformation. As Thomas says, “We need to understand the step we took moving from paper and pen to spreadsheets is only digitization. Not digital transformation.”

If you are using spreadsheets daily to manage things such as dispatch, logistics planning, pricing, quoting and more, what you are failing to do is leverage the opportunities that your rich data sources allow you combined with the benefits of improving decades old processes.

Actionable Data

As an industry, we are starting to generate a good amount of actionable data, some of this already in real time. Any static tool such as Excel does not have the capability to capture, analyze and guide instant decisions. If you combine this with the lack of capabilities to integrate with your other business systems such as ERP, Point of Sale, Dispatch or CRM, there is your perfect lost opportunity.

And there is precedent in highlighting the shortfalls or mistakes that have been made by using spreadsheets for business functions.

- JP Morgan Chase – in 2012, an Excel error resulted in a $6.2B trading loss, also known as “The London Whale” debacle.

- TransAlta – in ٢٠٠٣, an Excel error caused this Canadian power generator $٢٤M when they bought more U.S. power transmission hedging contracts at higher prices than it should have.

No Workflow

One of the issues is there’s no workflow to help manage data collection, reviews, and adjustments when Excel is used for business processes. As a result, organizations run into version control issues with multiple versions of Excel spreadsheets being emailed between users.

Thomas is very clear where spreadsheets fail, in relation to our relative business focus. “They fail to capture the opportunities around dynamic pricing, they fail to capture the opportunities around better targeted pricing; in dispatch, they fail to create decent productivity planning, they fail to mimic what the customers of our customer want.”

Thomas goes on to say, “spreadsheets don’t allow you to capture real time exception and opportunity management.” Thinking this through, most businesses have invested in Telematics or GPS tracking of some sorts. The lack of real-time feedback to your plan will cost you both dollars in wasted trucking or haulage and will keep your stretched workforce on their toes.

So, what are these opportunities? Simply put, in logistics, you can bring some deliveries forward if there is a gap, or, you can sell something at a premium if for some reason it is in short supply or the market conditions change to make the product more valuable – a competitor running low on the same product, a competitor breakdown or similar. The scenarios are nearly limitless.

If you are currently using printed price lists or manual shipping sheets, moving to spreadsheets is definitely an improvement. But it is 2023, and we can and should be doing better than that. In essence, by using Excel, for example, you are just replicating in Microsoft what you did with your old paper-based systems. Warts and all. I had a colleague when I worked for Lafarge who used to say “be careful with software, we don’t to remain as dumb as we were, but faster.”

What is the Answer?

According to Thomas, you need to start by describing a business objective. Take the space where INFORM operates within the industry.

Objectives should be something like, “I want to reduce my fleet size by 15%” or “I want to lower my logistics unit costs by 12%” or “I want to be 20% more on time.” Then start analyzing how you are going to achieve this. Software alone will not give you these results, as the “do what I want button” doesn’t work reliably without aligning the software to the business objectives. Once that is out of the way, making everybody use the software correctly will get you to your final goal.

Skipping all these steps is like acquiring a copy of Microsoft Word and hoping to become a good author – possible but highly unlikely.

When Thomas looks at aggregates dispatch that is managed by Excel, the advantage that INFORM’s software offers straight out of the gate is the comprehensive support for bulk orders. It comes with a great deal of business flexibility using its AI approach to schedule loads. So, if I need to replenish a stockpile for tomorrow start of day, between the available equipment, I can schedule orders and drivers to ensure this is done on time without impacting the time critical replenishment of concrete or asphalt plants.

With specialized software, you can execute individual real business needs by addressing the real issue. Take delivery trucks for example: understanding the client performance on the receiving end of an order can eliminate issues such as overservicing or underservicing. Decisions can be made dynamically.

Our own software, Price Bee, is a CPQ product. What is CPQ? It is Configure, Price, Quote. What does configure mean? Well, for Price Bee, the Configure part is fitting all the components of the potential order together. For example, in aggregates, depending on how our client wants to run their business, the configuration may be selecting the desired products, and maybe their alternatives. The Pricing is applying your desired Price strategy, whether that be discount based, margin based, market segment focused, a product category, volume tiers etc. The Quotation piece is the system that takes that configured price to the client.

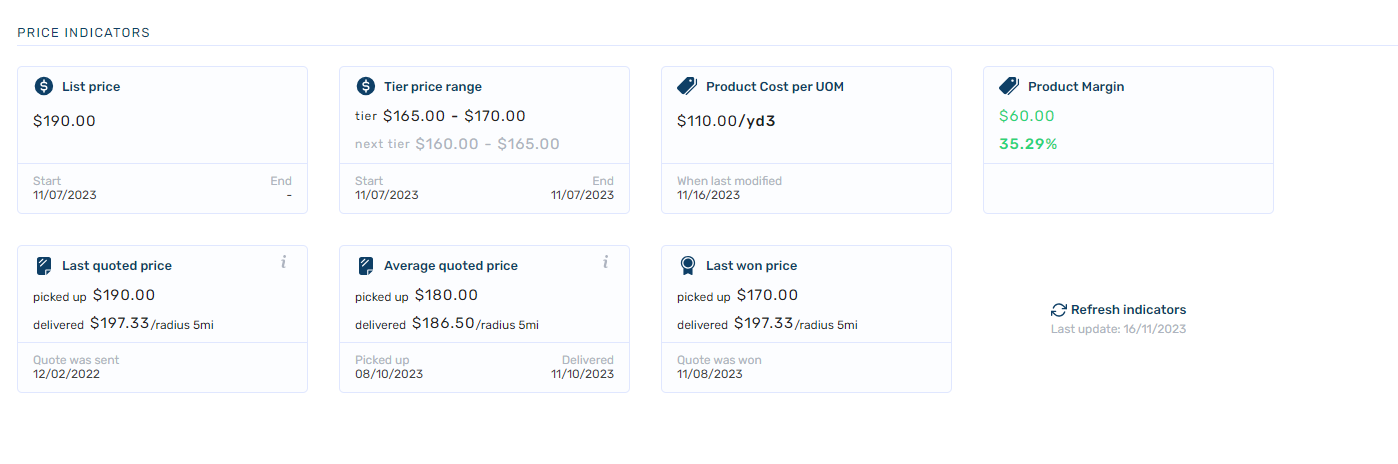

The complexity of this important function (CPQ) is far greater than a spreadsheet can perform. Take for example the pricing indicators that are available when preparing a quote in Price Bee. When we quote, we want to ensure we will extract the highest price, taking into consideration many factors.

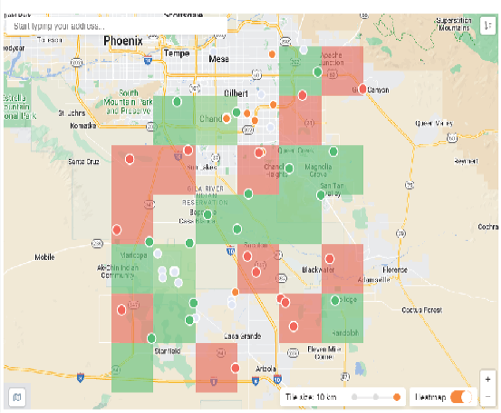

In this example, we can see the power of visualization with heat maps, displaying areas where you as a company have some type of advantage or disadvantage. The amount of data, the live integrations to ERP, CRM and POS systems, the analysis and display of that data is far beyond the capabilities of a spreadsheet.

In this second example of what live analysis cloud-based software can provide, we see some indicators that a user can use to define a price for a material, at a given location. In this information panel, you can see the latest list price for the product, as well as any price tier details, the product cost, margins by % or absolute, the latest quoted price within a 5-mile radius, the average quoted price and the price that you last won a quote for that product. Try doing that in a spreadsheet!

And what is the upside of being able to process and report sales performance? The revenue increase of a properly devised pricing strategy, executed in a system such as Price Bee for aggregates is between 6-9%. Obviously, the migration from spreadsheets to cloud based software in your sales processes is a great investment.

Who is INFORM?

INFORM is a global pioneer in AI-powered optimization software for ready-mix concrete, aggregates and cement logistics. Designed for use by large and medium-size companies, INFORM’s AI-powered transport planning and execution software enables dispatchers and planners to easily perform complex, time-critical calculations – moving more payloads with fewer trucks each day.

The software features business line-specific optimizers which are integrated in one central tool. Delivery schedules are updated every 90 to 120 seconds. Applying the software, dispatchers are free to focus on higher-level tasks and enhanced customer service. The software interfaces with existing Enterprise Resource Planning (ERP) systems and connects with trucks through telematics and uses the latest GIS and routing technology.

Companies gain a clear competitive edge and other measurable benefits by applying INFORM’s solution. In addition to increasing their loads per truck per day by up to 30%, customers have reported logistics unit cost savings ranging from 7-20% and a 10-30% reduction in fleet size.

INFORM has been providing its software to the global building materials industry for more than 25 years. Big and medium size players like Heidelberg Materials, Holcim and CRH have been using algorithms, real-time information and automated decision-making to manage and optimize their fleet of trucks ever since with amazing results.

To explore, visit www.inform-software.com/roadtoai.