How Top Plant People Use Quoting And Sales Planning To Their Advantage.

By Barry Hudson

In the high-stakes world of aggregate plants and rock quarries, every grain of sand, every pebble, counts. Especially when margins are as small as they are in this industry. But it’s not just about what’s underfoot; it’s about foresight, planning, and a dash of savvy tech-use.

In this article, we will be discussing the following topics about aggregate plant and quarry product pricing, quoting, scheduling and planning:

The Rocky Road of Forecasting and Planning

Picture this: A bustling quarry, loaders rolling, crushers roaring. In the middle of this gritty ballet, there’s a constant juggle – predicting sales in an industry as stable as a seesaw. Construction trends ebb and flow, funding factors play their part, and here you are, trying to read the future in a pile of rocks – AND you want to make some money on all of the hard work.

In an age where technological advancements redefine industries, the aggregate sector is no exception. Traditional methods, once reliant on pen and paper for sales and customer interactions, are swiftly transitioning to digital platforms.

A prime example of this digital revolution is the case of Peckham Industries, a prominent player in the Northeast U.S. aggregates industry. Their adoption of state-of-the-art applications such as Price-Bee.com, a Quotation and Price Management system developed specifically for the industry exemplifies this transformation. And more recently, smaller tech companies are teaming up to bring their products together for greater transparency and to unlock new areas for efficiency and profitability.

Some Challenges in Detail

- Predicting Sales and Production: It can be like weather forecasting, but with more trucks and less Doppler radar. So much can be unknown.

- Diverse Clientele: Asphalt plants, ready-mix plants, landscape yards – they all want a piece of your rocky pie. Their needs can fluctuate greatly.

- The Funding Factor: A large portion of the construction materials industry relies on federal and state funds. Lettings and projects can move demand by months.

- Understanding Pricing: Having a complete picture of your market, projects won and lost, competition’s capacity can be a challenge when it comes to pricing and quoting.

Understanding Your Market, and Pricing and Quoting for Profit

Inefficiency and lack of precision in traditional sales methods within the aggregates industry has made maximizing margins at the time of quoting a major challenge. Traditionally, sales teams relied heavily on manual, paper-based methods for quoting prices and managing customer interactions.

This approach was not only time-consuming but also prone to inaccuracies. It limited the ability of sales personnel to quickly adapt to market changes, analyze competitive data, and optimize pricing strategies.

The lack of a streamlined, digital solution hindered their ability to effectively manage customer relationships and leverage real-time market intelligence, ultimately impacting their competitiveness and operational efficiency.

Other industries have used systems built for the masses with some success. But these solutions can be total overkill for what you might need, they might cost a significant amount, and be difficult to implement, train and use.

Now, there are people working to solve this problem in the niche of construction materials quoting and pricing. People who are from the aggregate industry felt the frustration and decided to set off on improving this process for the companies that are innovative or smart enough to see the opportunities that digitizing the sales process offers.

Scheduling Sales at Your Plant

In the dynamic and challenging world of aggregate plant management, the ability to effectively schedule sales is crucial. Traditional methods, often involving spreadsheets, whiteboards, and frequent meetings, present numerous challenges.

Whiteboards, while visual, offer limited space, require constant updating, and are not easy to share. Excel spreadsheets, though versatile, can lead to redundant data entry and sharing difficulties as well. Moreover, scheduling meetings, though necessary, often result in outdated data as soon as a customer changes an order.

Enter PlantDemand, a game-changer in this arena. This software streamlines the entire scheduling process, transforming how plants manage their sales and orders. It creates a centralized platform, eliminating the need for multiple, disjointed systems.

This innovative tool reduces the time and effort spent on repetitive data entry and scheduling meetings, ensuring that the most current data is always at hand. By adopting PlantDemand, plants can focus more on their core operations and less on the cumbersome administrative tasks, leading to enhanced efficiency and productivity in the highly competitive aggregates industry.

Traditional Method vs. Potential Issues and Shortfalls

White boards: Limited area, must take photos to share, multiple times info must be entered.

Excel: Sharing can be a challenge. Redundant entry of data. Requires employees to maintain. Issues with equations.

Scheduling meetings: Time consuming. Data is outdated as soon as the meeting is over and a customer changes something.

In-house systems: Can be customized for business need, but require large resources and personnel to maintain and stay up-to-date with software and security.

Communicating What Your Customers Need

As an industry, we have to be honest with ourselves. We are not good at planning or reconciling what we said we would do, versus what we actually did. Examples of this are:

- How many times do we check that the quantity we sold a customer is the same quantity that the customer was quoted?

- How many times do we check that the supply rate which a customer stipulates is the same as what was delivered?

- How often do you communicate with the asphalt and ready-mix plants you supply to make sure you can adapt to meet their needs?

Each of these situations costs you, the producer, time and money. Each of these situations causes you inefficiencies. The inefficiencies can be from under or over utilization of plant capacity, ineffective logistics planning and execution.

PlantDemand.com is a great aggregate, ready-mix and asphalt scheduling software that has revolutionized plant scheduling. It is a cloud-based software that addresses scheduling and material needs issues and is currently used by various companies including Granite Construction, New Enterprise Stone & Lime, Vulcan Materials among others.

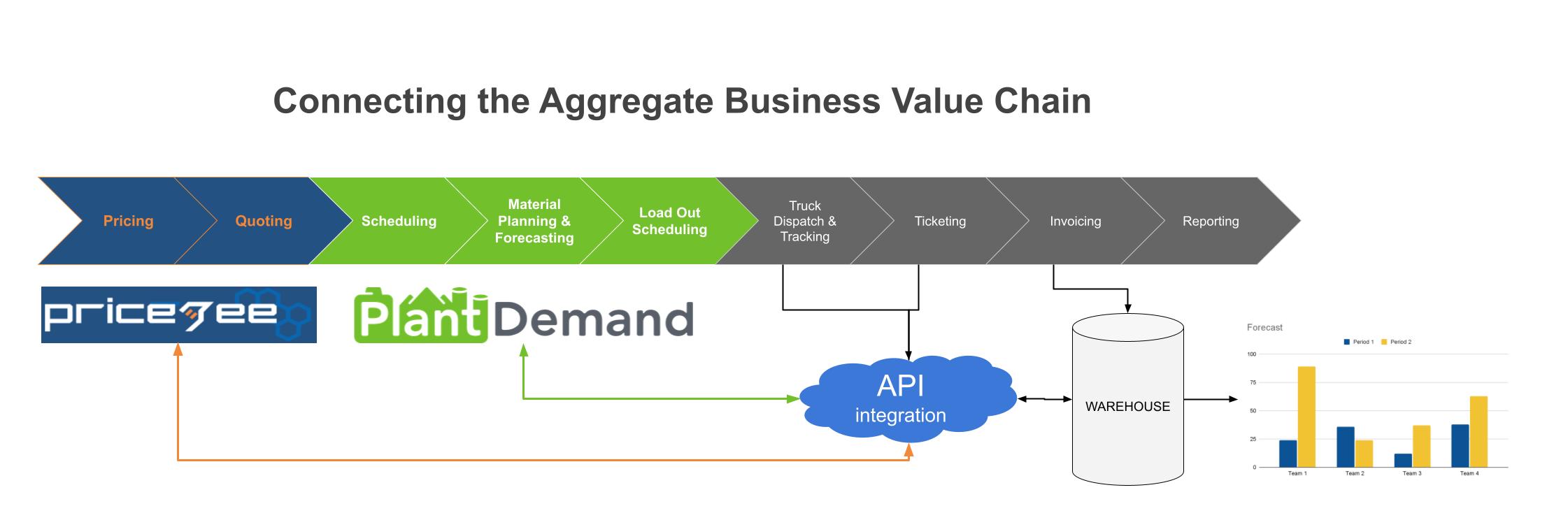

“Combining our planning and scheduling capabilities with a quotation function was a logical next step in an effort to connect another link in the value chain,” said Dennis Schaaf, co-founder and product manager of PlantDemand. “The data required to ensure efficient planning at plant level, backlogs, capabilities, etc. is the same data that is used for sales analysis and quotation closing. So combining this data through API integration is a great value for our plant folks.”

Planning Production and Balanced Inventory

Understanding your sales drives how you choose to produce (mode, rate, hours, etc.). Balancing inventory and understanding demand can affect your pricing and also your competitors on specific products. Piles in your yard are money spent. So managing cashflow in your aggregate plant is a must. Imagine the power that is available to a company that has an industry specific quotation package that is synced to a scheduling system like PlantDemand.

As an industry, we are renowned for the lack of harmonization between production and sales. Combining Price-Bee.com and Plantdemand.com gives us an insight on how the operational and sales functions can be both transparent and profitable.

Picture this scenario: You have a quotation tool that is linked to your scheduling and inventory management tools. When a project or bid is being created in the quotation tool, the operations people can see what sales are working on. Even at the very beginning of the sales cycle, with a bid in preparation, the production requirements are instantly visible to the production teams. Any issues relating to inventory or capacity can quickly be identified and acted upon.

Let’s face it, in the aggregate industry, managing inventory effectively can be achieved through two main strategies.

- The first approach involves increasing production to meet demand.

- The second strategy focuses on adjusting pricing.

By altering prices, a company can either secure more orders or ensure that the orders they do receive are at the desired or necessary rates.

The Value of Combining the Best Technology Solutions for Aggregate Plants

To wrap up, using the best technology solutions in aggregate plants is a game-changer. We’ve seen how tools like Price-Bee.com and PlantDemand can make a big difference. These tools help plants manage quotes, sales, plan better, and keep track of inventory in a smart way.

In the past, aggregate plants used old methods which were slow and often not accurate. Now, with these new technologies, things are changing for the better. These tools are designed just for the construction materials industry, which means they fit perfectly with what the plants need.

By using these technologies, plants can see what they need to produce and sell more clearly. This helps them make more money and waste less time. It’s like having a clearer map for the journey in this business.

In short, when aggregate plants use these new tech tools, they work smarter, not harder. This means they can do better in the market and stay ahead of the competition. It’s an exciting time for the industry, with these technologies leading the way to a more successful future.

So plan a little time to work with folks who build tools like these, and see how much value you can bring your business by trying new innovative ways of doing things in the aggregate and construction materials industry.

Barry Hudson is with Price-Bee.com, contact him at [email protected].