Knowing what kind of slurry pump to use can make an enormous difference for any aggregate operation. The wrong type of pump will lead to inefficiency, premature pump breakdowns and inevitably spending more to replace it, according to Northwest Pumps.

One factor that will affect which kind of pump, is whether the inside is metal or has a rubber lining. This choice can change how much money you spend on said pump and its replacement parts. Here are a few things to take into consideration when deciding what kind of slurry pump to use.

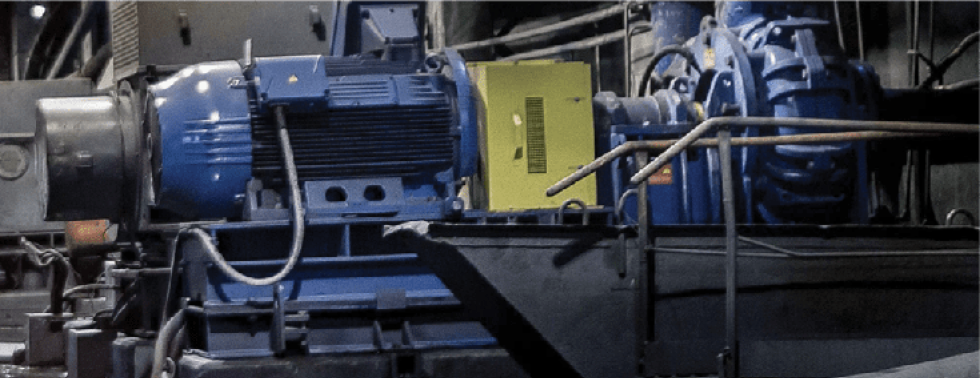

Metal Pumps

The aggregate industry prizes metal pumps because of their tough nature. While all slurry pumps receive wear and tear, certain metals will withstand damage better than others, such as plastic or urethane. However, this property also means the initial cost will be higher than the rubber-lined pumps. Servicing periods, though more expensive, will also be more sporadic to offset the costs. Another consideration for using steel piping is the contents of the slurry. If a slurry contains rocks that are 3/8-in. or larger, then a rubber-lined pump might wear out too quickly. Knowing what makes up your slurry solution and how the pump’s materials react are crucial for making your pumping choice.

Rubber-Lined Pumps

Rubber-lined slurry pumps will cost less than their metal counterparts. Because the insides of this pump are rubber instead of metal, this pump will require replacing the interior parts much sooner than a metal pump. However, because of the smaller intervals, the cost of these replacement parts is significantly smaller than replacing an entire pump down the road.

Recent technology has allowed the rubber-lined pumps to last longer than previous versions, meaning the gap in lifespans between metal and rubber-lined pumps are shorter than ever. Additionally, one key piece of information to determine if a rubber-lined pump will work for your system, is knowing exactly what is pumping through it. A wrong combination of rubber with the sand within the slurry can cause a pump to wear out prematurely.

Northwest Pump, www.nwpump.com