Selecting Screen Media For Recycled Materials.

By Lars Bräunling

Recycled material processing is a challenge. Different types of recycled materials have unique properties that require specialized screening options. There is no one-size-fits-all solution. Instead, screen media manufacturers work with recycling operations to get the right fit for the type of material being processed.

Let’s take a closer look at a couple of different types of recycled materials and learn how one producer found high-vibration screens to be a cost-effective way to meet the associated challenges.

Recycled Asphalt Pavement

Recycled Asphalt Pavement (RAP) increases the affordability of road projects by cutting down on transportation costs. Recycling onsite keeps material on hand, minimizes downtime and keeps work moving. However, asphalt tends to get sticky when recycled. RAP retains much of the oil needed to bind asphalt. On one hand, this can be considered a benefit because fewer binders must be added. But the downside is that oil, combined with retained moisture can lead to severe blinding during processing, especially in hot weather.

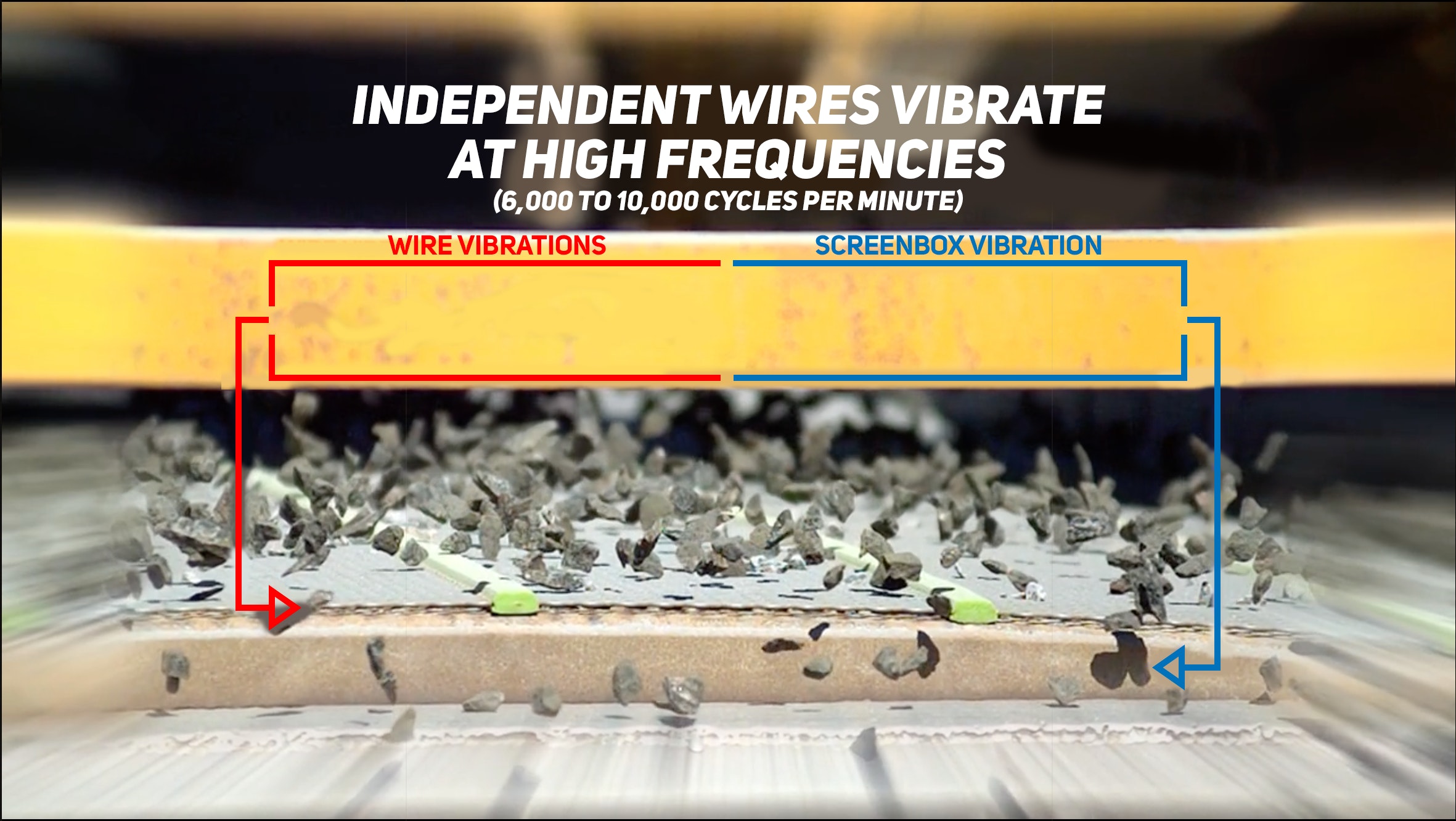

High-vibration wire screens are the solution to blinding when screening sticky materials like RAP. Unlike some designs that feature rigid woven wire, high-vibration screen media has wires, magnifying the vibrating screen’s vibration and reaching frequencies between 6,000 and 10,000 strokes per minute. That’s more than significant; it’s game changing. The high-vibration frequency and independently vibrating wires dislodge stuck material and virtually eliminate blinding issues, even in challenging applications.

Crushed Aggregate Recycling

Crushed aggregate recycling can be reused in driveways, pathways, garden beds and more. However, depending on the type of material, different screening issues can occur. Here are two examples:

- Crushed concrete: wet operating or feed conditions do not make a significant impact on productivity.

- Recycled gravel: the smaller particle sizes allow for lighter wire diameters to be utilized.

Each recycling application is impacted by different variables that require its own configuration of screen media, which makes it critical to work closely with a screen media manufacturer or certified local dealer to achieve optimal production.

The good news is that no matter what crushed aggregate is being screened, it will benefit from high-performance screen media. Independently vibrating wires are extremely effective at dislodging stuck material, offsetting the challenges posed by traditional designs like woven wire.

A New Way to Screen

One West Coast producer in the United States struggled to increase the productivity of their recycled concrete and asphalt products when using woven wire screen media. A change was needed, so a screen media manufacturer worked with them to evaluate their challenges and provide a customized screen media solution. Since installing high-vibration wire screen media, the operation has seen a dramatic increase in uptime, with virtually no shutdowns for cleaning pegged or blinded material. As an added bonus, this screen media lasts four times the lifespan of the producer’s previous woven wire screens, nearly cutting consumption costs in half.

Working with a manufacturer who offers a wide range of wire and opening sizes equips operations with the best screening solution for their recycling application. A manufacturer’s ability to advise on a case-by-case basis helps producers find the customized screen media solution that makes them successful in any recycling application.

Lars Bräunling is MAJOR’S director of product technology. For more information go to www.majorflexmat.com.