Powerful Products, The Hottest New Equipment, High-Tech Solutions And More Await Aggregates Producers At This Year’s Show, March 14-18 In Las Vegas.

By Mark S. Kuhar and Josephine Patterson

Rock Products

Grand Lobby, Booth GL12594

Stop by the Rock Products booth to pick up print copies of the magazine, learn about Women in Aggregates and our new Construction Materials Carbon Management; web portal; and be sure to meet with representatives from Burgex Mining Consultants who will show you Rock Products’ digital Aggregates Atlas as well as its state-of-the-art Mineralocity Aggregates platform that can generate weeks or even months’ worth of actionable mineral market analysis research.

Rock Products, www.rockproducts.com

Astec Industries

Booth C30235, D1200

For its aggregates customers, Astec Industries’ Materials Solutions Group has designed and launched its newest portable high-frequency screen plant, the PTSC2818VM for display at ConExpo-Con/Agg. The plant’s innovative design and size is the first of its kind for the industry, featuring an 8-ft.-wide high frequency screen.

Astec’s newest PTSC plant is equipped with an 8- x 18-ft. (2.4 x 5.5 m) top deck and an 8- x 12-ft. (2.4 x 3.7 m) bottom deck. The patent-pending screen design features externally mounted vibrators at the ends of the tappets for a more aggressive screening action.

This unique design creates a higher G-force and reduces heat load from material to motors as compared to single, center-mounted vibrators. It also allows for easier maintenance and adjustments. The screen is equipped with hydraulic operating angle adjustment, a fines collection hopper, top- and bottom-deck discharge chutes and an aggregate spreader.

Astec Industries, www.astecindustries.com

BKT USA

Booth W41766

For more than 30 years, BKT has successfully focused on specialty segments such as agriculture, construction, mining, industrial, earthmoving, port, ATV, and lawn and garden.

At ConExpo-Con/Agg, the company will show:

• BKT EARTHMAX All-Steel radial tires, designed to withstand the harshest conditions. With a full product line for all equipment types, BKT EARTHMAX tires have the tread pattern and compound to meet the demanding needs of any work environment.

• EARTHMAX SR 30 (E-3/L-3) All Steel radial tires, dual-purposed for loaders and articulated dump trucks. The multi-layer steel belts and the rigid block pattern provide excellent traction, stability and durability. The special cut-resistant compound makes EARTHMAX SR 30 the ideal solution for a variety of harsh operating conditions.

• EARTHMAX SR 46 for rigid haul trucks is BKT’s innovative response to severe rocky, abrasive and harsh mining environments. This tire has been specifically designed to carry heavy loads offering superior resistance to cuts and chips as well as a long tire life cycle.

BKT, www.bkt-tires.com

CASE

Booth W40800

CASE Construction Equipment is putting the construction industry on notice with a promise that “You’ll See the Difference” at ConExpo-Con/Agg. The more than 180-year-old manufacturer will highlight “The New CASE” at the industry’s largest North American trade show – showcasing groundbreaking new equipment, exciting new partnerships and a range of new solutions designed to help contractors get more work done, easier and more profitably than ever before.

“A focus on innovation is extremely important but it isn’t enough to support our industry in 2023 – our dealer network, our equipment, and our team will build on our legacy and turn heads as we make moves to greatly enhance equipment users’ productivity,” said Terry Dolan, vice president — North America, CASE Construction Equipment. “At ConExpo-Con/Agg, CASE will launch exciting new machines, reveal some unexpected products and our booth will clearly demonstrate our plan for making work easier and more productive.”

“All great companies and great brands evolve,” said Rebecca Bortner, director of marketing, CASE Construction Equipment. “‘The New CASE’ marks the next step in our evolution as a brand and we’re looking forward to making some waves in the industry.”

The CASE booth will showcase industry and business solutions to make contractors’ jobs easier – this includes more than 30 new machines, tons of new attachments, ingenious new technology and educational sessions with tips on best practices around technology, equipment, fleet management and more. CASE will also host new product presentations in the booth Tuesday through Friday at 10 a.m., 1 p.m. and 3 p.m., in addition to having loads of knowledgeable team members ready to help industry members get more done, with greater ease than ever before.

“2023 will be a year where we reshape the industry and help businesses and equipment owners do better in all facets of their work,” concluded Dolan. “ConExpo-Con/Agg is just the start.”

CASE, CaseCE.com/SeetheDifference

Caterpillar

Booth F9127

The stage is set for Caterpillar’s largest exhibit to date at ConExpo-Con/Agg where the company will highlight its latest products, services and technologies while paying tribute to those who build the world’s infrastructure. The company’s 70,000-sq.-ft. outdoor demonstration arena will anchor the massive display known as Operator Stadium located in the expo’s Festival Lot.

New Caterpillar Technology, Services and Sustainability hubs provide visitors the opportunity to look beyond the iron for ways to increase operating efficiencies and improve machine uptime. Visitors will find new and current models and battery-electric machine prototypes during the show.

The extensive Cat equipment display in the Festival Lot includes more than 30 machines, including model unveilings and battery-electric model prototypes with charging stations. Visitors will see two main equipment demonstrations each day; one focused on the latest Cat Technology, and one that will spotlight the company’s full equipment lineup. Additionally, Caterpillar will be providing unique daily spotlight demonstrations that will take a deep dive into key industry topics including improving fuel efficiency and jobsite efficiency, the evolution of technology, and convenient, scalable solutions for all customers.

The new Cat 950 medium wheel loader on display offers premium performance and simple-to-use technologies to help boost operator efficiency and increase productivity, while extended service intervals help lower maintenance costs. Visitors will be treated to a preview of the Next Generation Cat 926, 930 and 938 small wheel loaders – slated for production in late 2023 – which feature new technologies designed to make work easier, a reimagined operator environment and extended service intervals.

Cat, www.cat.com/en_US/campaigns/event/conexpo-2023.html

CDE

Booth C30269

CDE will debut new equipment, new projects and showcase the waste recycling solutions that are transforming dirt into dollars across North America.

The company will exhibit in booth C30269 (Central Halls 3-5) in the indoor exhibition area.

CDE said it “co-creates with its customers to design and engineer solutions that maximize the use of natural resources while unlocking value from waste streams.”

With 30 years of experience in providing optimized, proven solutions to customers across the world, CDE’s technologies have successfully diverted more than 100 million tons of CD&E waste from landfill.

At ConExpo-Con/Agg, CDE will be joined by its customers from across North America to champion the value of recycling construction, demolition and excavation (CD&E) materials into high specification outputs.

Darren Eastwood, business development director at CDE, said, “Our focus at the show will be demonstrating to the industry how CDE washing solutions are turning dirt into dollars. We’re seeing rapid growth in the waste recycling space and are awash with waste recycling enquiries as a result. CDE is leading the charge in supporting the industry to realize value from construction, demolition and excavation waste, as well as by-product from the crushing and screening processes.

“These materials are often overlooked or discarded, but they hold significant commercial value. With the efficiency and reliability offered by our proven washing solutions, materials producers can unlock that value to transform these materials into high-quality recycled sand and aggregates for construction use and boost profitability,” Eastwood concluded.

Equipment on display will include CDE’s AggMax scrubbing and attrition system, its Counter Flow Classification Unit (CFCU) for density separation and EvoWash sand classification and dewatering system.

The majority of equipment on display at the show is destined for a new C&D waste recycling wash plant in the United States.

Visitors will have the opportunity to see the washing solutions up close, as they are guided by CDE experts around the equipment currently utilized at sites across North America.

CDE, cdegroup.com

Command Alkon

Booth N12315

Command Alkon is a global supplier of integrated solutions for construction materials producers, with customers in over 70 countries worldwide. Command Alkon offers industry-specific hardware and software systems for producers, suppliers and haulers of ready-mixed concrete, concrete products, aggregate, asphalt and cement.

The Command Alkon’s family of products addresses batching, dispatching, dispatch optimization, fleet and workforce management, quality control, bulk materials distribution, plant and quarry automation, transportation planning and performance, process controls, back-office operations, performance management, enterprise content management, voice-based scheduling and mobile computing.

Here are some descriptions of its focus products at the show:

Dispatch – Cloud-based dispatch offers centralized management of all plant data and pricing and a consolidated view of total customer demand and operational capacity each day. Extend real-time information and communications with customers and field personnel and speed up invoicing and payment cycles.

Inventory and Replenishment – Remove spreadsheets and phone calls from your inventory management playbook and capture a new level of visibility to manage your day and plan the next day with ease. Automatically forecast inventory needs, place vendor orders, and replenish inventory based on scheduled daily orders.

Customer Portal – Customer Portal offers delivery and order tracking for material suppliers and their customers. This cloud-based, mobile solution provides a convenient online experience for creating, managing, and tracking orders 24 hours a day.

COMMANDassurance – Sensor data – including slump, temperature, volume, water additions, W/C ratio, drum rotation, and direction for each load – goes into the cloud and is readily available in real time to all who need it. Soon, measuring air-content in real-time will be available, giving complete and unparalleled visibility into concrete properties.

Command Alkon, www.commandalkon.com

Deister Machine Co.

Booth C31549

With rising production costs and rigid specifications, it takes heavy-duty vibrating equipment to meet the challenge – big-capacity, cost-cutting, hard-working Deister screens and feeders – customized to fit the application. Ruggedly built and requiring minimal maintenance, Deister screens and feeders deliver dependable production even under the most adverse operating conditions or when handling the most abrasive materials.

Deister engineers are ready to talk with producers about specific screening and feeding solutions at ConExpo-Con/Agg. In booth C31549 in Central Hall, attendees will take an up-close look Deister’s extra heavy-duty triple-deck inclined vibrating screen – and its heavy-duty horizontal triple-shaft vibrating screen.

Since 1912, the family-owned Deister Machine Co. has been recognized for building innovative vibrating screens with superior quality. Its heavy-duty equipment ensures reliable day-to-day performance. Units are designed with extra protection at all vital points, and extra-heavy duty bracing and frame members that ensure long vibrating frame life.

Deister engineers ensure that every screen and feeder is designed to deliver greater efficiency while lowering operating costs-per-ton. Deister equipment is American-made and backed with 24/7 parts and service support, and a dedicated dealer network.

Deister Machine Co. Inc., www.deistermachine.com

Develon

Booth F9153

Develon, formerly known as Doosan Infracore North America, will promote the company’s new global brand and logo, as well as several new products at ConExpo-Con/Agg.

The company’s new name and logo will integrate new brand values and its commitment to creating the smart construction solutions of tomorrow. Visitors to the exhibit will be able to see the new brand in action, hear the story of why the new name was chosen and see what’s next for the company.

“Fans of our current offerings will be delighted that the equipment will remain unchanged and continue to deliver the powerful, reliable solutions admired worldwide,” said Alice Banach, senior marketing manager.

The exhibit (F9153) in the outdoor Festival Grounds area will showcase a sampling of the company’s full line of construction equipment, the exclusive Transparent Bucket for wheel loaders, a battery-powered engine and several new machines, including the company’s dozer line. Attendees are encouraged to stop by the exhibit to see how the company continues to evolve as a single source provider of the latest construction equipment.

Cutting-edge technologies such as Concept-X demonstrations, safety features and electrification will be featured. The exhibit will showcase autonomous equipment, the new Smart X-Care fleet management service and the topography-scanning drone Concept-X Xite Cloud.

The Concept-X autonomous worksite will feature three live demonstrations each day, along with other new products. First exhibited in 2019 with an autonomous Doosan wheel loader and excavator, Concept-X is a smart control solution to tomorrow’s worksites. It can survey worksite topography via 3D drone scanning, establish operational plans based on that data, and operate heavy construction equipment such as excavators, wheel loaders and articulated dump trucks without human intervention.

Concept-X technology paves the way to the worksite of the future with equipment-driven construction sites, freeing human personnel to tackle complex data analytics and management tasks. Continuous Concept-X demo pit footage will be played simultaneously on a large screen and a three-screen brand tower in the Develon exhibit.

Develon, na.doosanequipment.com/en/develon

Durex Products

Booth C32567

Durex Products Inc. will display its screen media, liners, wear parts and screen accessories in booth C32567 at ConExpo-Con/Agg. The company offers numerous innovative urethane, rubber and wire screen media options, which allow customers to fine-tune production and increase tons per hour, while keeping products in spec and lowering operating costs.

Durex has offered premium screen media technologies since 1965, including its well-known Livewire, Armor, Accuslot, Vibraspan and Vibraclean wire screens, as well as modular urethane and rubber screens. Wear liners for aggregate and concrete equipment, wear parts and screen accessories round out the company’s offerings.

Durex, durexproducts.com

Eagle Iron Works

Booth C31773

Eagle Iron Works has offered customers reliable, easy-to-operate equipment to handle washing and classifying applications since 1872. After celebrating 150 years of business in 2022, EIW is excited to expand its product line and show the industry that the company will continue meeting the demands of the industry for the next 150 years.

During ConExpo-Con/Agg, EIW will not only highlight the classic equipment for which it is known but they will also display a brand-new line of equipment that will complete its already extensive list of washing equipment. ConExpo-Con/Agg will be the first place for dealers and customers to see this system in-person.

“EIW has been successful for the last 150 years because we design and build the heavy-duty equipment that the industry needs. We listened to the customers and industries around us and have developed a new system that we’re excited to launch,” said Tim Miller, business line director – EIW.

In addition to the launch of its new equipment, EIW will showcase its Eagle genuine parts and gear reducer programs – all designed to ensure that your operation is always running with minimal downtime.

EIW, www.eagleironworks.com

General Kinematics

Booth S5872

Vibratory equipment manufacturer and system integrator General Kinematics (GK) of Crystal Lake, Ill., will exhibit at booth S5872 in the Silver Lot. GK’s presence is more prominent this year, with five industry-specific units running in the booth. Additionally, the company’s expanded capabilities within GK Systems will be displayed.

GK has the largest selection of vibratory machinery equipment available, while the GK Systems Group engineers long-lasting and profitable C&D recycling systems. Combined, GK provides integrated solutions stretching from equipment and parts through installation and commissioning.

The vibratory units showcased are GK’s Aggregate Screen, Paramount II, Feeder, and De-Stoner. After the show, the Aggregate Screen will ship directly to the customer’s location in North Carolina. Within GK’s family of brands, the Tuffman Equipment Company will showcase a trommel and belt conveyor.

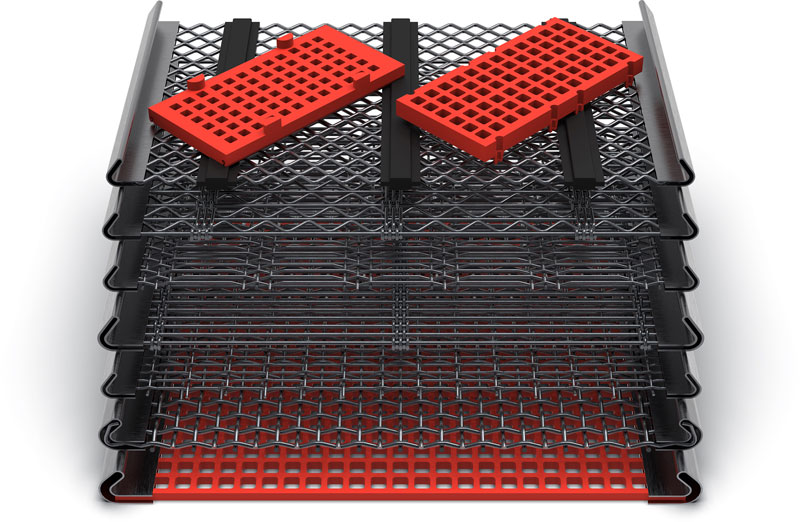

Elliott Tribble, market director, aggregates, commented, “I am looking forward to the 2023 ConExpo-Con/Agg. I’m excited for the industry to see our 6- x 16-ft. triple-deck wash screen, equipped with our new Duro-Deck modular screen panels. Both products are customizable and high-performing products to fit all screening applications.”

“After three years of significant growth within our company, we added more installations to our C&D customer base and expanded our Turn-Key System offerings. We look forward to seeing you in Las Vegas and discussing new opportunities,” stated Bob Huffer, regional sales manager.

General Kinematics, www.generalkinematics.com

Haver & Boecker Niagara

Booth S5948

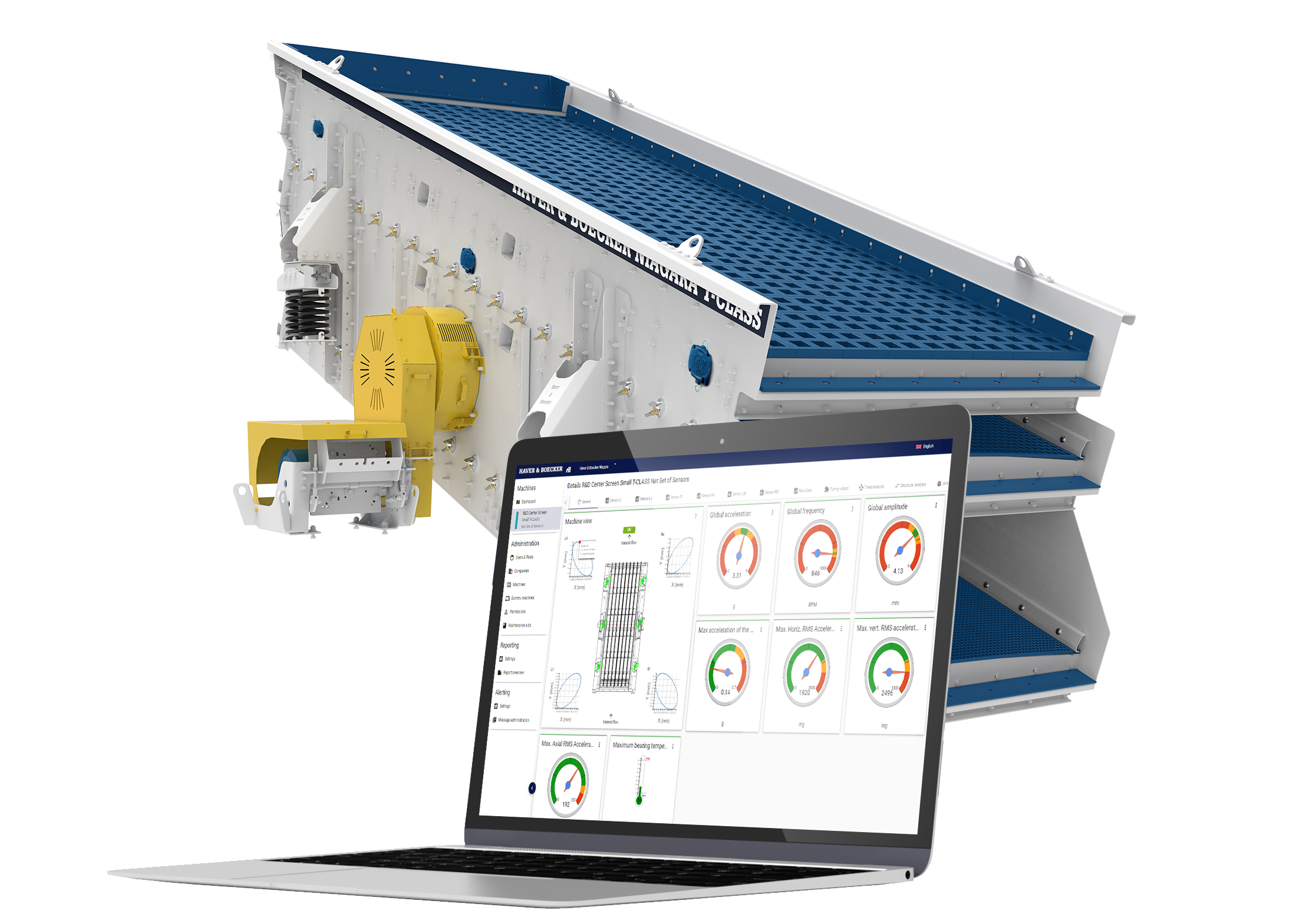

Haver & Boecker Niagara offers Pulse Condition Monitoring (Pulse CM) as a part of their Pulse portfolio. The technology is designed to monitor the health of vibrating screens using modern algorithms and artificial intelligence. It provides accurate measurements and forecasts complemented by information that is easy to understand. Pulse CM is a wireless diagnostics tool that helps mineral processing operations be proactive, rather than reactive, when it comes to maintenance efforts. This leads to increased efficiency, decreased downtime and improved reliability.

Haver & Boecker Niagara is highlighting its Pulse Condition Monitoring technology, along with other innovative mineral processing products and services, during ConExpo-Con/Agg.

“Haver & Boecker Niagara has a history of developing solutions to help producers increase their uptime,” said Thiago Buoso, Haver & Boecker Niagara project and sales engineer. “Unexpected downtime is a huge source of lost revenue for producers, so we aim to create products and technology that prevent that. Additionally, there is a lack of reliable systems like this on the market. Pulse Condition Monitoring is the most detailed, accurate monitoring system available to customers.”

Pulse Condition Monitoring is one level of the Pulse portfolio, accompanying the company’s Pulse Vibration Analysis and Pulse Impact Testing. Similar to Pulse Vibration Analysis, the Pulse CM system analyzes data to help users get the most out of their equipment. Unlike Pulse Vibration Analysis, Pulse CM uses permanently installed sensors to monitor equipment 24/7.

The system captures real-time information on monitored equipment and provides alerts via e-mail when it detects the first sign of potential problems. By constantly monitoring the accelerations of the vibration screen, Pulse CM provides a forecast of the equipment’s dynamic condition in intervals of 48 hours, five days, and four weeks. The system detects anomalies that will point an operation’s maintenance team to specific areas of the equipment that may require attention. With consistent use, Pulse CM will accurately point out and predict critical issues and advise when to schedule maintenance, along with what to focus on during that planned downtime.

To collect all data from the body and drive components, Pulse CM is equipped with a gateway that can connect with up to 20 wireless sensors, within a radius of up to 246 ft. (75 meters). Using a cellular signal or Wi-Fi from the plant, it will send all data to the Haver & Boecker Niagara cloud, available through the company’s web app. The sensor configurations are customizable and placed on both the body and bearings of the vibrating screen. The gateway can also be positioned between two screens operating near one another.

Haver & Boecker Niagara’s accompanying app displays all the information in an easy-to-use portal, providing users with a full overview of equipment in real time. They can access detailed information specific to each of the body and bearing sensors to identify the equipment’s operating condition and the health of each component.

Haver & Boecker Niagara, www.haverniagara.com

Hyundai Construction Equipment

Booth W42501

Hyundai Construction Equipment will use its ConExpo-Con/Agg display at booth W42501 in the West Hall to showcase new, current and future model machines. With a standard 9-cu.-yd. bucket, Hyundai will introduce its largest capacity wheel loader, the new HL986A.

Other current-model full-sized wheel loaders, excavators and wheeled excavators will also be on display in the company’s exhibit. Hyundai will conduct live demonstrations of the safety, technology and telematics systems.

“Hyundai brings to ConExpo-Con/Agg our strongest and deepest lineup of products, along with exciting, alternative-powered working prototypes and some of the industry’s top safety and support systems, plus our team of sales, support and product experts,” said Stan Park, president, Hyundai Construction Equipment Americas. “This also marks our first ConExpo-Con/Agg since the recent Hyundai acquisition of Doosan Infracore, now known as Develon. Visitors will see some of the promising, early results of our collaborative efforts, including one of our new articulated dump truck models.”

At the show, Hyundai will also take the wraps off its newly available model HS120V skid steer loader and HT100V compact track loader. The two new compact models are powered by a four-cycle, turbocharged, electronic-controlled Hyundai 4HTI4 diesel engine that meets Tier 4 Final emissions standards.

Three new compact excavator models will also make their debut at the show – the HX35AZ, HX40A and HX48AZ. Hyundai said the models will feature a new “Tiger Eye” design, which includes large cabs, larger windows, enhanced operator comfort, a 5-in. full-color LCD monitor, a new auto safety-lock function and free use of Hyundai’s HiMATE telematics system for five years.

In addition to the diesel-powered excavators on display, Hyundai will exhibit two alternative-powered prototype excavators. The Hyundai HW155H is a prototype wheeled excavator powered by a hydrogen-fueled engine. The 2-ton prototype Hyundai R19E is an electric-powered compact excavator.

Hyundai Construction Equipment, www.hceamericas.com

John Deere/Wirtgen

Booth S5020, W40844

John Deere will have its largest presence ever at ConExpo-Con/Agg. Totaling 80,000 sq. ft. of booth space, John Deere and Wirtgen are combining forces for the first time at ConExpo-Con/Agg, encompassing a 70,000-sq.-ft. booth outside in the Silver Lot (S5020). Inside the West Hall (W40844), an additional 10,000 sq. ft. is dedicated to the future of John Deere technology in the construction space.

The John Deere and the Wirtgen Group presence offers customers an engaging experience and an all-encompassing snapshot of the future of construction through industry-leading equipment and technology.

In addition to its expansive and interactive booth experiences, exhibition attendees can anticipate the following from John Deere and the Wirtgen Group:

- One cohesive booth showcasing both John Deere and the Wirtgen Group’s latest machines and technologies.

- 70,000 sq. ft. of outdoor space displaying world-class John Deere and Wirtgen Group equipment, technology and application experience.

- 68 machines on display between John Deere and the Wirtgen Group.

- Six machines that feature SmartGrade control functionality. Wirtgen Group machines equipped with the latest technologies such as: Wirtgen Performance Tracker, AutoPilot 2.0, 3D Paving, Smart Compact, Spective Connect.

- Nine compact construction machines on display such as skid steer loaders, compact track loaders, compact excavators, and compact wheel loaders.

- Nine electric or hybrid electric John Deere and Wirtgen Group machines on display.

- 36 world premieres of brand-new equipment across the construction, roadbuilding and compact construction segments.

- Four production systems, showcasing the current priority areas for John Deere and the Wirtgen Group, including Aggregates, Site Development, Roadbuilding and Underground.

- One center feature area for the future generation of Deere built excavators.

- Three educational sessions featuring commentary from John Deere and Wirtgen Group experts.

“Being ‘Close To Our Customers’ we understand our contractors desire to have conversations relevant to their production system needs. John Deere and the Wirtgen Group designed the booth layout with a production system strategy in mind,” the company stated. “To assist our customers, four production systems, include Aggregates, Site Development, Roadbuilding and Underground, were created to emphasize their core business areas. Each production system will showcase key components, equipment, and features relevant to their needs and presented first-hand by John Deere and Wirtgen Group brand representatives.”

John Deere/Wirtgen, johndeere.com/Vegas2023

Keestrack

Booth C31386

Keestrack, with its Texas-based U.S. headquarters, will be at ConExpo-Con/Agg with its American, Canadian and Latin American dealers to showcase what’s new.

Machines on show at the Keestrack booth C31386 in the Central Hall include the R5e impactor. The completely newly designed R5e impactor of Keestrack is a full electric plug-in. It also has a plug-out connection to power additional equipment. The impactor used in aggregate production, recycling, quarrying and mining can be powered via mains connection, or via any gen set unit, in case there is no connection to the grid available.

Other machines include:

- H4e cone crusher.

- K6 scalper screen.

- R3 impact crusher.

- B7 jaw crusher.

Keestrack’s vision on sustainability guides the company. “A focus on sustainability is at the core of our company as this is the origin of our business. Producing and recycling valuable raw materials is what mobile crushing and screening is all about,” said Frederik Hoogendoorn, vice president sales and marketing. “Our efforts are definitely having a positive impact on the ecological footprint.”

Throughout the years Keestrack has been active, besides recycling, in the quarrying, mining and aggregates industry. “As these heavy-duty industries need very powerful drive systems Keestrack kept on searching for alternative drive systems. From load sensing hydraulics, to e-drives and now we are going to ZERO drives, equipment with no combustion engines on board but only electric motors. This request is also a pull from mostly the North European market. This way we want to protect the planet and save money at the same time,” Hoogendoorn said.

Keestrack, keestrack.com

Komatsu

Booth W42044

For ConExpo-Con/Agg, Komatsu will be in booth W42044 and the theme for the show will be “Creating value together.” With the right products, latest technologies, actionable data and dealer support, Komatsu helps its customers create value to help achieve their visions for productivity, efficiency, sustainability and safety.

The Komatsu booth will feature equipment, technology and service solutions that address:

- Construction.

- Energy/utility.

- Forestry.

- Quarry.

- Smart Construction/Smart Quarry.

- Sustainability and electrification.

- Waste.

To showcase tools that support operation optimization, the Komatsu booth will address:

- A sustainability/electrification roadmap.

- Technology implementation.

- Workforce optimization.

Working together with its customers, its booth will demonstrate how Komatsu’s machines and solutions can help our customers:

- Optimize fleet capabilities.

- Extend the life/improve the value of machines.

- Operate with safety as a priority and reduce employee downtime.

- Leverage the latest technology to improve efficiencies and productivity.

- Conserve resources and reduce fuel consumption.

- Upskill and retain employees and use them in the most productive ways through leveraging the right training and latest technologies.

On the show floor, the company will be featuring its latest electric offerings alongside brand-new and recently introduced machines. A sampling of Komatsu machines that will be on the floor:

- PC210E (with Smart Construction Retrofit) electric excavator.

- PC900LC (with Smart Construction Retrofit) excavator.

- HB365LC-3 (with Smart Construction Retrofit) hybrid excavator.

- D71PXi-24 intelligent dozer.

- HD465-8 mechanical haul truck.

- PC230F-11 processor.

- PC360iLC-11 intelligent excavator.

- WA600-8 wheel loader.

Komatsu, www.komatsu.com

Liebherr

Booth F9253, S80821

ConExpo-Con/Agg provides Liebherr a platform to showcase new, innovative products and technologies that emphasize digitalization, alternative drives and efficiency, allowing the Liebherr team to be on your site anytime, anywhere.

Liebherr is one of the largest exhibitors with two booths totaling 60,400 sq. ft. The outdoor booth (Festival Grounds, booth F9253) at the show highlights more than 30 machines and exhibits within an area of over 60,000 sq. ft. (5,500 sq. meters).

Several new products and technologies are showcased from seven of Liebherr’s product segments including earthmoving, material handling, concrete technology, mobile and crawler cranes, tower cranes, and deep foundation machines.

In addition, Liebherr presents the latest component technologies in the South Hall (second floor, booth S80821). Visitors can also experience on-site activities within the outdoor booth supported by more than 250 Liebherr employees from 10-plus countries.

Liebherr, www.liebherr.com/conexpo

Luff Industries

Booth C30853

Luff Industries Ltd. manufactures quality conveyor components, including idlers with patented polymer end caps and pulleys with an industry leading rim thickness, to an international market.

The company’s booth is located in the Central Hall (C30853).

Using Luff components, companies have been increasing the performance of their conveyor systems for over 40 years. Recognized for innovative products, quick turnaround times and industry-leading warranty, Luff conveyor components can be found in a variety of heavy industrial material handling applications.

Due to these different application requirements, Luff manufactures one of the most complete product lines available.

Luff Industries, luffindustries.com

Magna Tyres

Booth N10741

Netherlands based Magna Tyres is returning to ConExpo-Con/Agg with a 1,200 sq.-ft. booth (N10741) in the North Hall.

Taking center stage at the Magna Tyres booth will be a quality selection of six tire patterns – 20.5R25 Magna MA01+, 26.5R25 Magna MU30, 29.5R25 Magna M-Terrain, 35/65R33 Magna MA07+ and 37.25R35 Magna MA02, which will cover the mining and earthmover market sectors. Plus, the 12-16.6 PR12 Magna M-Skid TL for the construction industry.

Stephan Van Leeuwen, sales director OEM at Magna Tyres, said, “Our main priority for returning to ConExpo-Con/Agg this time will be to meet new potential customers and to build on Magna Tyres’ emerging brand awareness in North America. We will also be looking to further strengthen our market sectors. Will be returning to the show with our Utah-based North American dealer CMC Tire who also has operational bases in Nevada and Colorado.”

Magna Tyres, [email protected]

MAJOR

Booth C32267

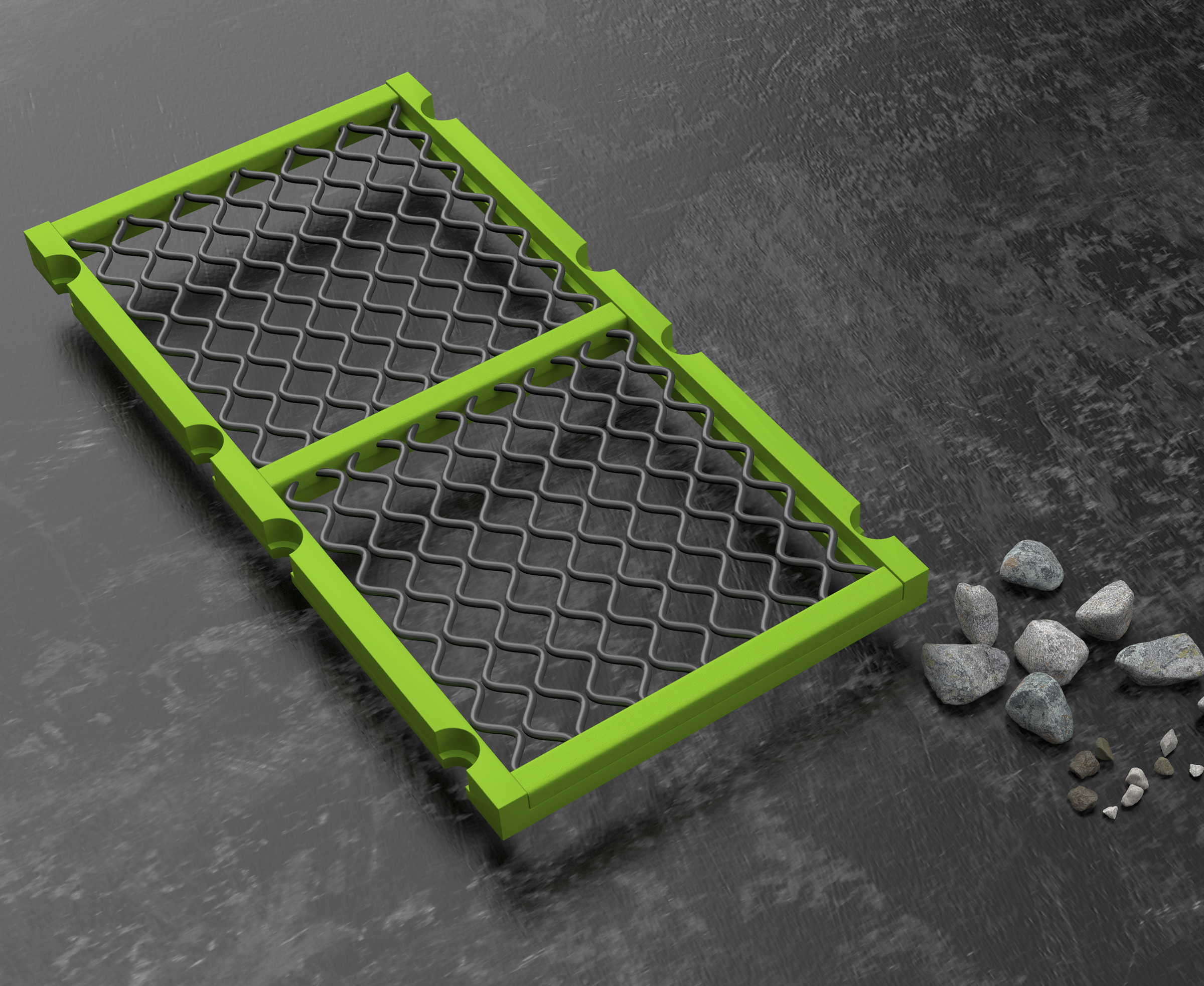

MAJOR is highlighting its FLEX-MAT Modular PLUS screen media panels at booth C32267 during ConExpo-Con/Agg.

“We’re always looking at ways to help producers get the best end product. What better way than to optimize the design of our efficient FLEX-MAT product for even better performance,” said Bernard Betts, president of MAJOR. “FLEX-MAT Modular PLUS is just that. A proven, reliable solution to achieve heightened screening performance and improve the bottom line.”

The efficiency-enhancing characteristics of all FLEX-MAT screen media, including the Modular PLUS series, are created by bonding OPTIMUMWIRE – the industry’s longest-lasting wire – with distinctive lime-green polyurethane strips rather than weaving them. This allows wires to vibrate independently from end to end under material contact.

The high frequency of the wires – 8,000 to 10,000 cycles per minute – adds to the vibration of the screen box – 800 to 900 cycles per minute – to speed up material separation and passing. The increased screening action improves material throughput while virtually eliminating near-size pegging on the top decks and fine material blinding and clogging on the bottom decks, resulting in a lower cost of production per ton. Additionally, the media offers up to five times longer wear life than traditional woven wire and produces a cleaner retained product.

Like MAJOR’s traditional FLEX-MAT panels, the new PLUS series is available in a variety of patterns, including the D, S and T series. The D-series features a standard square pattern, which is ideal for precise sizing. The S-series maximizes open area, virtually eliminates blinding, and reduces fine contamination. The T-series enhances screening for particles below 0.059 in. (1.5 mm) and features small openings to minimize blinding. The screen media is secured through either grooved, step, or pin and leg panels.

FLEX-MAT Modular PLUS screen media panels are available in either the patented OPTIMUMWIRE or 304 stainless steel wire. In addition to modular panels, MAJOR’s signature FLEX-MAT Modular PLUS media is available in tensioned sections for use on crown decks.

MAJOR, www.majorflexmat.com

Mazio

Booth W43211

Mazio Attachments LLC is an Italian manufacturer of specialized attachments for the construction, demolition, recycling, mining, aggregates, excavation, scrap and forestry industries with engineering and manufacturing facilities located in the United States, Italy and Colombia.

The company will have its experts on hand in the West Hall at booth W43211. Visitors will learn how Mazio’s innovative attachments will help them save time and money in the quarry and on the jobsite.

Mazio’s newest innovation for 2023 is the Tilt-Rotator for excavators. Tilt-Rotators have seen great interest in Europe, and they are growing in popularity within the United States. These supplemental attachments work with excavator tools, such as grapples, buckets, or shears, to provide more versatility and precision. They not only rotate 360 degrees, but they also tilt side-to-side by up to 55 degrees. This ability reduces the need for the operator to move the excavator while performing tasks – increasing productivity and efficiency.

The Mazio Tilt-Rotator features a hydraulic quick coupler that allows the operator to remain in the cab while changing tools. It enjoys maintenance-free operation, with no grease points and no cylinders. It allows access to narrow spaces and on urban projects with large or small equipment. In addition to the Tilt-Rotator, the Mazio booth will feature its complete line of demolition tools; hydraulic breakers; and wear tips for grinders, breakers, shears, crushers, pulverizers and processors.

Mazio’s experts work in tandem with its dealers to provide producers and contractors with guidance on ways to increase their productivity and profits, helping them to ensure success.

Mazio, www.mazio.us

McCloskey

Booth S5411

An updated look for the McCloskey product line is being unveiled, with a modern look for the company’s product portfolio. The new design maintains the globally recognized color brand, protecting its equity, while infusing it with a new look in line with new products being introduced at the show.

Located in the Silver Lot at booth S5411, the more than 15,000-sq.-ft. space showcases the newest products from McCloskey International, as well as new features designed in collaboration with key customer input. Of note, the new color scheme brings a consistent colored chassis and galvanized steel handrails, creating a unified and a more contemporary look across the product range.

“As McCloskey and its allied brands grow in response to rising demand globally, we continually are seeking new ways to enhance the brand while ensuring we maintain the equity we have built over time,” said Toni Laaksonen, senior vice president, McCloskey International. “This update reflects our commitment to the foundation built on the McCloskey green while refreshing the product line with a modern approach.”

The world is facing some major challenges, and North America is no exception. The increasingly urgent search for carbon-neutral and emission reduced sustainable products has led McCloskey to develop a number of options for its customers, including electric and dual power (hybrid) alternatives. At ConExpo-Con/Agg the company will show a S190 Dual Power screener along with a ST100TVR Dual Power stacker as representative of the advances in McCloskey’s product innovation. Crushers are also rolling out in electric versions in 2023, including the J4E and J6E, with more products entering the market throughout the year.

A 1,200-sq.-ft. information pavilion provides a bird’s eye view of the equipment, as well as a venue for customers to meet and mingle with dealers from around the world. McCloskey’s allied brands, McCloskey Environmental and MWS Washing Systems, will be showcased in the main pavilion, along with an Aftermarket display and information zone to meet with representatives on the broad offering of after sales support and services available.

Products on display at the show represent all categories of McCloskey equipment, as well as those from McCloskey Environmental and MWS Equipment.

McCloskey, www.mccloskeyinternational.com

McLanahan

Booth C31372

With 187 years in business, McLanahan Corp. is still providing innovative solutions and set to return to Las Vegas for ConExpo-Con/Agg with first-time equipment displays alongside its entire family of companies, including Eagle Iron Works, Anaconda and first-time exhibitor RubbleCrusher.

At booth C31372, McLanahan will showcase a Horizontal Screen Over Screw Portable Plant for the first time at any trade show. While this is not a new piece of equipment for McLanahan, it is a highly demanded configuration that the company’s dealers requested be on display due to its popularity.

This configuration can be hauled using a semi-truck, showing the simplicity of setup at any operation, as well as the convenience of easy transportation between sites. This portable plant features all McLanahan designed and manufactured major equipment pieces, which means customers are getting the same field-proven, heavy-duty equipment that is often used in stationary set ups in a compact, portable unit.

In conjunction with the portable plant, McLanahan will display its UltraDRY Dewatering Screen in the booth. The UltraDRY is a modular, skid-mounted McLanahan Dewatering Screen that can be added to a new or existing system to create a drier, ready to sell product that has been known to come off the dewatering screen at a moisture content as low 7%. As a skid-mounted plant, it can also be used in conjunction with equipment like the portable plant and easily transported between sites as well.

McLanahan will also have a variety of displays showcasing its washing equipment, crushers and screens, tailings management solutions, pumps and more – all of which have the goal of helping producers meet the challenges and demands of their ever-changing industries.

With a complete product range, an experienced process team, and a strong, local dealer network, McLanahan is committed to giving its customers solutions that are going to maximize their production and profitability.

McLanahan, www.mclanahan.com

Montabert

Booth W42229

Visitors are encouraged to visit Montabert in the West Hall, booth W42229, during ConExpo-Con/Agg, to learn about new developments in rock breaking and demolition tools.

New products to be highlighted at the show include the SD Compact Breaker for rock breaking. The SD line is designed to fit compact carriers such as mini-excavators and skid steers. Additionally, Montabert’s new line of Silent Demolition Tools, including grapples, processors, fixed and rotating pulverizers, and scrap shears, offer contractors multiple options for demolition and recycling applications.

Montabert’s SD series of hydraulic breakers is designed for use on skid-steer loaders, backhoe loaders and mini-excavators, providing versatility and productivity to accomplish multiple tasks with a single carrier, a single operator, and a single attachment. With fewer wear parts and no tie rods, the SD offers quick and easy maintenance in the field or the shop.

Bushings, pins, and tools can easily be replaced in the field without removing the breaker from the carrier. The fully enclosed, soundproof cradle reduces vibrations transferred to the carrier, as it limits noise on the jobsite. Lightweight, yet heavy-duty housing protects working parts and hoses. A unique energy chamber acts as hydraulic shock absorber and reduces pressure variations in the hydraulic circuits to provide consistent energy to the breaker. The SD line includes seven models for compact carriers from 1 ton to 12 tons.

Montabert, www.montabertusa.com

Philippi-Hagenbuch

Booth W42435

Philippi-Hagenbuch will showcase its custom haul truck solutions at booth W42435 during ConExpo-Con/Agg.

“Producers are always looking for ways to improve productivity and continued increases in demand are driving operations to look even more closely at their equipment and efficiency. ConExpo-Con/Agg provides the perfect opportunity for operations to discover new solutions for their productivity challenges,” said Josh Swank, vice president of sales and marketing.

“At Philippi-Hagenbuch, we are excited to help attendees find new ways to keep up with the demand for raw materials by maximizing the capability of their haul truck fleets. We’re also looking forward to sharing how haul truck customizations can increase productivity during an educational seminar at the show. The session will discuss how customizing a new truck or retrofitting an off-highway truck or fleet can maximize payload capacity, reduce dump times and downtime, eliminate carryback and minimize repair service and maintenance needs,” Swank said.

Some of the solutions the company will highlight at its booth include Autogate Tailgates, Rear Eject Bodies and HiVol Water Tanks. These are all custom engineered to fit the specific make and model of haul truck and to meet the unique needs of the operation.

Philippi-Hagenbuch, www.philsystems.com

Polydeck

Booth C31561

Polydeck, a provider of innovative modular screen media solutions, is set to continue pushing the boundaries of modular media at the upcoming ConExpo-Con/Agg show with the launch of its latest product offerings. The company, which has a reputation for delivering cutting-edge solutions to the mining, aggregate, energy and industrial markets, will showcase RUBBERDEX ULTRAMAX and METALDEX ULTRACLEAN, designed to improve the efficiency and effectiveness of the screening process.

ULTRAMAX is Polydeck’s latest addition to its RUBBERDEX product line, and it offers up to 57.6% open area, making it an excellent alternative to conventional wire cloth. With 77.23% more open area than competitor rubber media, RUBBERDEX ULTRAMAX is designed to provide superior performance and efficiency in the screening process. The product is ideal for customers looking to increase production with an efficient and easy to install screening solution in dry sizing applications.

METALDEX ULTRACLEAN is another new product from Polydeck that extends the company’s METALDEX product line. The product offers 9.5% more open area than competitor wire panels and provides more effective cleaning, throughput, and efficiency. The product is the perfect solution for customers looking for a screening solution that provides accurate sizing while maintaining high standards of cleanliness and efficiency.

“We are excited to launch these boundary-pushing products at ConExpo-Con/Agg,” stated Trey Rollins, director of marketing. “Our goal is to provide our customers with the best possible screening solutions, and these new products are a testament to our commitment to innovation and excellence. We believe these products add to the wide range of custom solutions we can provide our customers that will improve their screening production.”

At the show, Polydeck will have a team of application experts on hand to demonstrate the features and benefits of its latest product offerings. Attendees can also ask questions and learn more about how these products can benefit their operations.

Polydeck invites all trade show attendees to visit booth C31561 to learn more about its latest product offerings and how they can benefit from them.

Polydeck, www.polydeck/com/conexpo2023

Rokbak

Booth F8926

Rokbak is bringing a pair of its haulers and a strong team to ConExpo-Con/Agg to show exactly how the brand has become a major mover in both the U.S. and global market. ConExpo-Con/Agg will be the first time Rokbak haulers have been on display at a North American trade show.

The Scottish articulated hauler manufacturer is bringing both models to the largest construction show in North America, providing attendees with the chance to get up close and personal with the earth-moving machines and demonstrate exactly how they can offer grounded ‘Rok-solid’ performance stateside.

“We cannot wait to get back to ConExpo-Con/Agg and give the RA30 and RA40 pride of place on our stand,” said Paul Douglas, managing director of Rokbak. “We’re looking forward to getting as many attendees interacting with what we’ve got lined up as possible, as well as introducing people to our knowledgeable team who are keen to show off our robust and hardworking haulers. Rokbak will be there to show customers first-hand the quality our machines and why we’ve become known as one of the most reliable and trusted articulated hauler manufacturers in the market.”

Rokbak will be located at booth F8926 in the Festival Grounds, together with fellow Volvo Group companies Volvo Construction Equipment and Volvo Penta.

ConExpo-Con/Agg will be the perfect opportunity to highlight the machines’ abilities to benefit construction projects, talk to customers about how the haulers deliver new benchmarks in both performance and total cost of ownership and reinforce the company’s commitment to sustainability and journey to net-zero as part of the Volvo Group.

With sustainability in mind, the Rokbak event booth materials are all recycled or reusable. Two 40-ft. customized shipping containers, adorned in the recognizable Rokbak aesthetic, will be used for meeting rooms and product information displays. Following the event, these will be shipped back to Motherwell for reuse at future events.

Product experts will be ready and waiting to discuss the technical capabilities and key aspects of the haulers, welcoming everyone to the booth where there will be merchandise giveaways and competition prizes up for grabs throughout the event – as well as plenty of refreshments.

“Rokbak is seeing huge demand for its RA30 and RA40 articulated haulers in the United States,” said Robert Franklin, Rokbak’s director of sales – Americas. “The United States is leading articulated hauler demand globally with its huge infrastructure spend. There is a lot of construction activity at the moment around house and road building, so we are keen to meet with customers and potential customers at ConExpo-Con/Agg and discuss how the RA30 and RA40 can help with these projects.”

Rokbak, www.rokbak.com

RubbleCrusher

Booth S5276

RubbleCrusher will make its North American debut as part of the McLanahan family of companies at ConExpo-Con/Agg. RubbleCrusher will be introducing its compact, mobile crushing units to North America at the show, with a focus on expanding its global dealer network in the United States.

RubbleCrusher will showcase its portable and track-mounted jaw crushers at booth S5276 in the Silver Lot during the show. These crushers are fast to deploy on job sites and meet all Department of Transportation regulations.

The popular pull-behind portable crusher, RC150V, can be hauled by any full-size pick-up truck, simplifying setup at any operation. The RC150V unit weighs just under 7,800 lb. and enables the operator to recycle C&D waste materials for use on site, without having to pay to remove materials or bring in new aggregate for jobs. The RC150T offers the same features as the RC150V but is mounted on tracks, making mobility on site possible by remote control.

Based in Leicestershire, U.K., RubbleCrusher offers robust crushing and screening equipment across various industries to allow for on-site recycling of C&D waste materials and are looking to expand their dealer network throughout the United States. Stop by Booth S5276 to learn how a RubbleCrusher can benefit your application.

RubbleCrusher, www.rubblecrusher.co.uk

Sandvik

Booth S5254

Sandvik will showcase some of its newest innovations in surface drilling, rock tools, stationary crushing and screening, and parts and services at ConExpo-Con/Agg. The company will exhibit at booth S5254 in the Las Vegas Convention Center’s Silver Lot outdoor festival grounds.

Sandvik will launch Ranger DX910i, its latest flagship top hammer surface drill rig, together with new drilling tools. The shoulder-driven curved thread systems CT55 and CT67 increase productivity and reduce fuel consumption. The Ranger DX910i on display at ConExpo-Con/Agg will be equipped with the new high-power rock drill RD930C, which expands Ranger DX910i’s hole size range beyond existing DXi rock drill options.

The company will display its electric concept surface drill rig, which demonstrates advanced technologies that will be featured on future Sandvik surface rigs to support more sustainable and energy-efficient drilling. It will also showcase its Leopard DI650i, a surface drill simulator and the RockPulse system for optimizing Ranger drilling results.

Sandvik will also showcase its latest rock tools offerings at ConExpo-Con/Agg, including Tundo RH650 down-the-hole hammer, Sandvik Alpha 340 top hammer drilling tools, which feature an entirely new asymmetric thread, as well as LT90 top hammer drilling tools. The company will also highlight its Carbide Recycling Program for recycling customers’ worn carbide tools, improving sustainability across the value chain.

The technologically advanced Sandvik CH865i mid-range cone crusher will anchor the stationary crushing and screening display, which will also feature SAM by Sandvik, the ever-evolving “always on” digital assistant to support operational excellence in crushing and screening plants, as well as the next generation Sandvik Automation and Connectivity System (ACS-c 4.3) for optimizing crusher performance. Sandvik will also showcase its Sandvik CV217 vertical shaft impact (VSI) crusher as well as screening media and wear protection.

Sandvik’s parts and services exhibit at ConExpo-Con/Agg will feature an interactive display introducing My Sandvik Productivity for Boom Drills, a telematics solution providing easy-to-read dashboards for faster, fact-based decision making. Exhibit visitors will experience a live demo of Sandvik’s Expert Off-Site, an on-demand web-based service that instantly connects customers with Sandvik experts remotely, minimizing downtime costs typically associated with waiting for technical support. Sandvik will also highlight its extended warranty solutions and comprehensive equipment rental offering.

Sandvik Mining and Rock Solutions, www.rocktechnology.sandvik

Stedman Machine Co.

Booth C31761

At ConExpo-Con/Agg, Stedman Machine Co. will feature the company’s Grand-Slam HIS, which crushes many materials, ores, and aggregates to the proper size with one pass.

The crushing action of the Grand-Slam HSI delivers properly sized material the first time through. The Grand-Slam is available in 12 low maintenance, minimum downtime models with interchangeable breaker bars, breaker plates and side liners for all models. The efficient, front-opening design offers safe and easy access to the crushing chamber for maintenance and replacement.

Stedman Machine Co. is dedicated to treating customers like family. The company manufactures a complete line of high-quality size reduction equipment and provides professionally engineered custom solutions for material processing and handling needs that are tailored to fit your application, allowing you to concentrate on making high quality, cost-effective products..

Stedman, www.stedman-machine.com

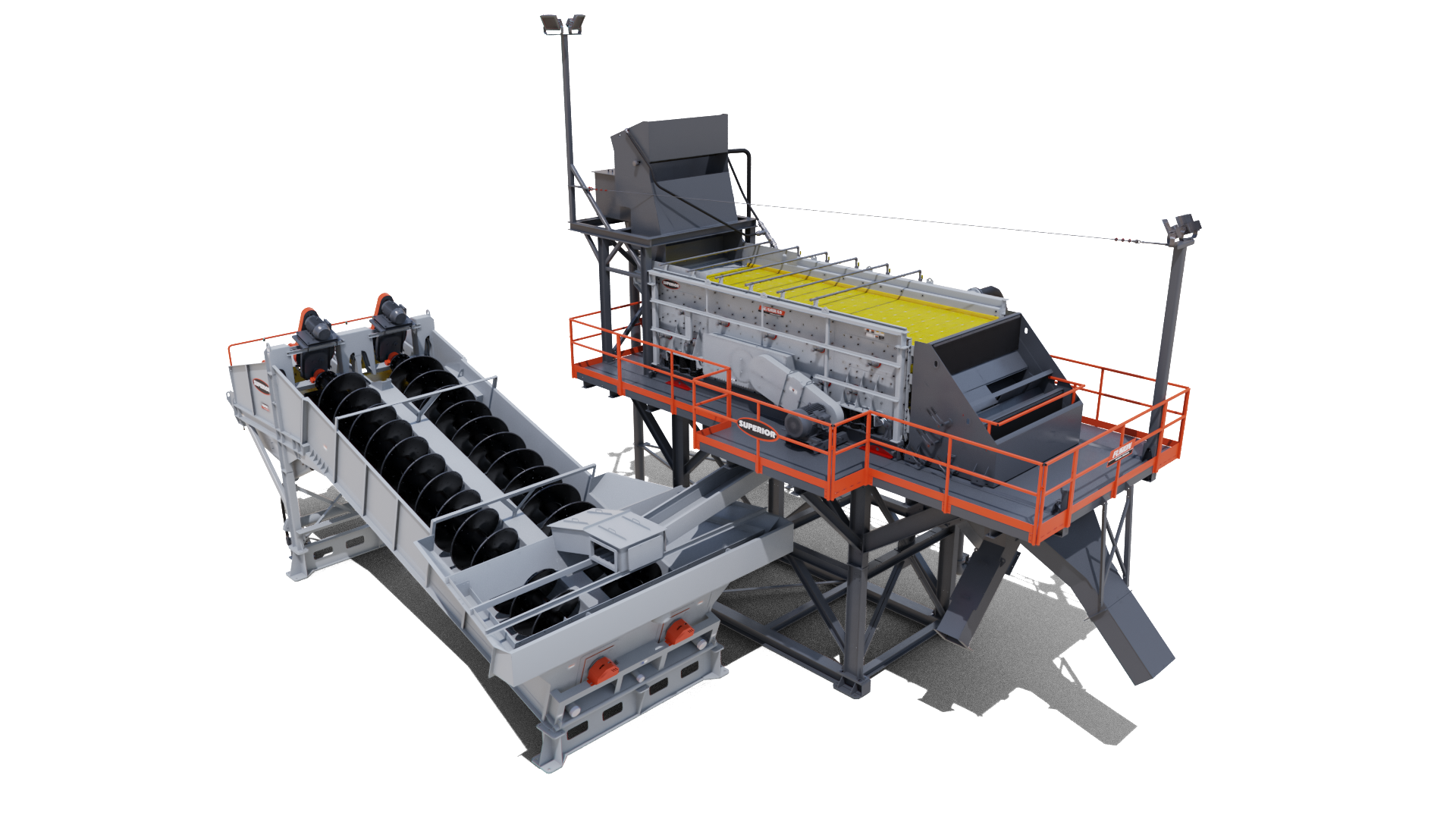

Superior Industries

Booth S5006

Superior Industries Inc. is planning to showcase more than 250-tons of its products at ConExpo-Con/Agg. At least eight of the products will be brand-new and revealed for the first time at the show.

For previous ConExpo-Con/Agg attendees, Superior wants you to know about its new booth location for the 2023 edition of the show. The manufacturer is relocating from inside Central Hall to outside in the Silver Lot.

“Inside is climate-controlled and comfortable, but our equipment and our people were born to be in the great outdoors,” said Corey Poppe, Superior’s communications manager. “In addition to our massive display of equipment, we’re incorporating lots of fun elements that only work in the open air. Things like 20,000 sq. ft. of artificial turf, grilling and grill giveaways, laid back patio-style seating, and maybe we’ll even roast a few marshmallows!”

Here’s a brief preview of some of the products Superior plans to showcase:

Expanded Cone Crusher Portfolio – Two brand-new cone models will be introduced and be shown alongside Superior’s trusted Patriot Bushing Cone. First, the Dakota Bearing Cone, which will earn credibility for its efficient use of horsepower per ton, a straightforward lubrication system, and a wide range of liner profiles. The other new cone crusher will be called the Endeavor Spider Bushing Cone. Operationally, it’s an uncomplicated design that accepts a wide range of feed sizes with an adjustable stroke for fine tuning. Superior also plans to display its Liberty Jaw, Valor VSI, and Sentry HSI crushers.

New Portable Plant Utilized in Recycling – Designed to process in recycle applications, Superior’s says its brand-new Portable Sentry HSI Closed Circuit Plant will get plenty of attention under the Vegas sun. It’s equipped with a patent pending recirculating conveyor, which centralizes the crusher feed for full utilization and extended wear life of the HSI’s blow bars. Other highlights include application-specific grizzly configurations, interchangeable cross conveyors, and screen media below the grizzly section.

New Quick to Erect Modular Wash Plant – According to Superior, its increasingly broad portfolio of Fusion Modular Platforms are a good match for aggregate producers seeking semi-static plants that are easy to install and maintain with a more economical price tag than portable plants or design-build projects. On display, the company plans to erect a 8- x 20-ft., three-deck Guardian Horizontal Wet Screen Fusion Platform with an Aggredry Dewatering Screen attached to one of the discharge points.

Telescopic Stacker Builds 200,000-Ton Stockpiles – In 2023, it will mark the eighth time Superior will display its famed TeleStacker Conveyor at ConExpo-Con/Agg, and each show there is new technology to showcase and new success stories to share. With radial travel, variable height and a telescopic conveyor, TeleStacker Conveyors stockpile material in a way that overcomes material segregation. This show, Superior will display a 42-in. x 170-ft. XTP Swing Axle model with a working automation panel that visitors can interact with in the booth.

Conveyor Components to Reduce Maintenance Duties – Once again, Superior will display a wide variety of its own conveyor components. In fact, the manufacturer is planning to show more than three dozen individual idlers, pulleys, scrapers, and other conveyor accessories. New products include a redesigned line of Exterra Belt Cleaners with some brand-new options, a modular Load Zone Skirting System for dust and spillage control, and unique Application-Specific Idler Bearing Seals for longer-lasting idlers in demanding conditions.

Superior Industries booth will be located in the Silver Lot, right inside what’s traditionally been known as the main entrance to the show. The booth number is S5006.

Superior Industries, superior-ind.com/conexpo

Terex MPS

Booth S5435

Terex MPS will unveil two new machines at ConExpo-Con/Agg 2023, the Cedarapids CRC1350S Portable Cone Crusher Plant and the Simplicity ESX “Extra Clearance” Series Horizontal Screen. The machines, along with the experienced Terex MPS team, will be situated at the show’s outdoor Silver Lot, booth S-5435, March 14-18 at the Las Vegas Convention Center in Las Vegas.

Russ Burns, sales director at Terex MPS, said, “We are excited to meet with our customers and distribution partners at ConExpo-Con/Agg 2023 and thrilled to be launching these two new units at the show. They illustrate our future product road maps, which focus our efforts on offering customer solutions that are safe, reliable and provide dependable production.”

Cedarapids CRC1350S Portable Cone Crusher Plant

The new Cedarapids CRC 1350S Portable Plant scheduled to launch in the third quarter of 2023, is designed for high production at lower costs per ton, while remaining highly portable. Featuring the enhanced TC1300X cone crusher with 400 hp and high efficiency roller bearings, not only increases the power overall, but increases the stroke from 45 mm to 70 mm.

Cedarapids engineers paired the TSV7203P, 7-ft. wide, triple-deck Horizontal Screen to deliver peak productivity while remaining easily portable. The configuration results in an increase throughput and improved quality product shape, making the CRC1350S Portable Cone Crusher Plant in a class of its own.

“The design of this plant was led by a series of interviews between our engineers and key distributors, the feedback of which resulted in the development of this popular closed-circuit layout. The CRC1350S exceeds our customer portable plant strategies, meeting our customer demands to yield higher production capacity, lower cost per ton while remaining highly portable,” explained Burns.

Simplicity ESX Extra Clearance Horizontal Screen

The ESX620 horizontal screen is the newest addition to the trusted range of screening solutions by Simplicity. The elliptical stroke, “Extra Clearance” ESX Series screens have taken the legendary oval stroke screen to the next level. The increased clearance between the screen decks provides easy maintenance access to the media. Upgrades to the drive train and suspension ensure that this screen still has the performance that customers can count on for years to come.

Outfitted with the latest design techniques and advancements utilizing state of the art engineering and production processes, the ESX Series screens are built stronger, run smoother, and will give customers peace of mind by providing industry leading durability.

Burns continued, “With a wide opening of 23-in. between the top and middle deck, and a staggering 27.5-in. between the middle and bottom, our experienced engineering team has designed this with the user in mind. Whether you are installing urethane media or specialty wire cloth, we have you covered with space large enough to inspect and replace any type of media you prefer, safely and with ease.”

Terex MPS legacy brands (Simplicity, Cedarapids and Canica) date back to 1921, when Simplicity was founded to build stationary shaker screens. This year marks the 100-year anniversary of Cedarapids, which was established in 1923 to manufacture portable plants and has evolved into the manufacturing of crushers, screens, and conveyors. Canica is the youngest of the Terex MPS brands, having been established in 1974.

Together the brands provide more than 250 years of industry knowledge and experience. All three were brought together under the Terex MPS umbrella in 2009 and continue to carry on their rich tradition of offering comprehensive solutions.

Simplicity ESX Extra Clearance Horizontal Screen

The ESX620 horizontal screen is the newest addition to the trusted range of screening solutions by Simplicity. The elliptical stroke, “Extra Clearance” ESX Series screens have taken the legendary oval stroke screen to the next level. The increased clearance between the screen decks provides easy maintenance access to the media. Upgrades to the drive train and suspension ensure that this screen still has the performance that customers can count on for years to come.

Outfitted with the latest design techniques and advancements utilizing state of the art engineering and production processes, the ESX Series screens are built stronger, run smoother, and will give customers peace of mind by providing industry leading durability.

Burns continued, “With a wide opening of 23-in. between the top and middle deck, and a staggering 27.5-in. between the middle and bottom, our experienced engineering team has designed this with the user in mind. Whether you are installing urethane media or specialty wire cloth, we have you covered with space large enough to inspect and replace any type of media you prefer, safely and with ease.”

Terex MPS legacy brands (Simplicity, Cedarapids and Canica) date back to 1921, when Simplicity was founded to build stationary shaker screens. This year marks the 100-year anniversary of Cedarapids, which was established in 1923 to manufacture portable plants and has evolved into the manufacturing of crushers, screens, and conveyors. Canica is the youngest of the Terex MPS brands, having been established in 1974.

Together the brands provide more than 250 years of industry knowledge and experience. All three were brought together under the Terex MPS umbrella in 2009 and continue to carry on their rich tradition of offering comprehensive solutions.

Terex MPS, www.terexmps.com

VDG (Van der Graaf)

Booth C32930

VDG is the leader in the design and manufacturing of drum motors for all types of belt conveyor applications, including mining and aggregate, ship loading and power generation.

GrizzlyDrive Series Drum Motors are designed specifically to operate in harsh, dusty, abrasive and extreme environments where performance and durability matter most.

With over 35 years of experience, continuous improvements through research & development, and in-house manufacturing in the United States and Canada using cutting-edge production technology, VDG ensures product quality, fast delivery, and exceptional customer support.

VDG, www.vandergraaf.com

Volvo

Booth F8926

Volvo Construction Equipment (Volvo CE) is building a one-of-a-kind booth experience at ConExpo-Con/Agg to help customers and other attendees be ready for an ever-changing business environment. The company shared its plans at a virtual press event attended by Rock Products.

With a theme of “Change Starts Here. Be Ready For It,” the 55,000-sq.-ft. Volvo booth, F8926 in the Festival Grounds, will feature the company’s newest and most popular products, cutting-edge services and technology in a dedicated Solutions Hall, two areas where attendees can test drive electric excavators and wheel loaders, construction industry influencers like the “Gold Rush” cast, and more.

In addition to two large operating arenas in the booth for electric machines, Volvo CE will also showcase its electric lineup expansion with the 23-ton EC230 Electric mid-size excavator and DD25 Electric asphalt compactor, which were introduced at the Volvo virtual press conference.

But a view into the future of the construction industry doesn’t stop with electric. Volvo CE will also display autonomous concepts, the world’s first hydrogen fuel cell articulated hauler, a remote-controlled unit and much more as the company works to help more customers reach their own efficiency and carbon reduction goals.

Also in the Volvo booth, F8926, will be the company’s next series of excavators, with a model unveiled the morning the show opens, and the upgraded L350 wheel loader. Tried- and-true Volvo excavators, wheel loaders, haulers and other products will also be on display with product experts ready to answer attendees’ questions.

Other Volvo Group companies will also be in the booth, including a truck from Volvo Trucks, engines from Volvo Penta and representatives from Volvo Financial Services.

Inside the Solutions Hall, attendees will be able to speak to experts about services and technology that can be tailored to the way they do business to grow now and well into the future. Solution offerings include:

- Site solutions that give customers tailored recommendations for their fleet – regardless of brand – to optimize site setup and reduce the risk of accidents.

- Business solutions to help customers streamline transactions, better control costs and maximize their uptime potential so they can stay focused on their core business.

- Financial solutions including valuable bundles and unique offers that help customers better manage cash flow during seasonal slowdowns.

- ActiveCare Direct, Volvo’s one-of-a-kind telematics machine monitoring and

reporting service, that provides proactive fleet intelligence to save customers time and money on diagnosing machine issues.

Attendees can also meet members of Discovery Channel’s “Gold Rush” cast Tuesday through Friday in the Volvo booth, as well as other popular construction industry influencers during a meet-and-greet Wednesday afternoon.

Volvo Construction Equipment, www.volvoce.com