Electronic and electric detonators may look similar and serve the same function, but they are very different, according to information developed as part of the MSHA Alliance Program.

Key Differences:

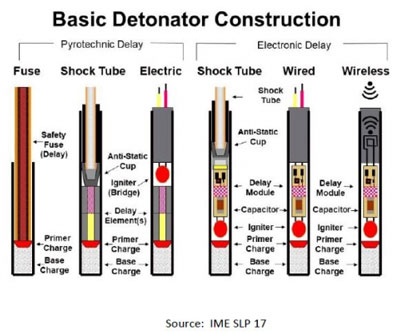

Lead wire attachment – As demonstrated in the figure below, the wire leads of the electronic detonator do not attach directly to a match head or bridge wire, like electric detonators. In the case of electric detonators, the direct connection of the wire leads to the matchhead or bridge wire makes them susceptible to initiation from static, stray current and/or radio frequency (RF) energy, whereas electronic detonators are not.

Added protection – Electronic detonators have other components to increase protection from extraneous energy sources: a spark gap device to protect against static discharge events (high voltage spikes from static build up on personnel, equipment, etc.), the use of current limiting resistors, amongst other devices or design features.

EMP – Both electric and electronic detonators can be damaged by an electromagnetic pulse (EMP). However, electronic detonators generally have built-in protection from this type of extraneous energy.

Pressure induced damage – Both electric and electronic detonators can incorporate dynamic and static pressure resistance, however electronic detonators (which use microchip technology and logic to provide timing and firing control) may have a higher susceptibility to damage.

Enhanced control systems – Electronic Blasting Machines are the only devices designed to provide password protection, programming capability and the energy levels needed to charge the electronic detonators in a circuit and send a fire command.

Interchangeability – Electronic detonating systems are unique and system components must never be interchanged. Users should read and understand all aspects of the system they use and follow the manufacturer’s recommendations. Electric detonators can be used with any appropriate firing device.

Training – Always consult your manufacturer for proper training information before attempting to operate any Electronic Blasting Initiation System.

Best practices – Always clear the blast area of personnel, vehicles, and equipment prior to hooking up to the firing device or blast controller. In addition, the blast area should remain clear until the charge on the electronic detonators have had sufficient time to bleed off.

The MSHA Alliance Program enables organizations committed to mine safety and health to collaborate with MSHA to prevent injuries, illnesses and fatalities in the workplace.