Update from the Mine Safety and Health Administration.

Approximately 250,000 miners work in around 12,000 metal/nonmetal mines in the United States, while approximately 83,000 work in around 1,000 coal mines. In 2019, The Mine Safety and Health Administration (MSHA) conducted 37,471 inspections at nearly 13,000 mines employing 330,000 miners, which resulted in 99,663 citations and orders. MSHA inspected all underground mines at least four times in 2019, and it inspected surface mines and facilities at least twice, as required by law.

Of the nation’s mining operations, none met the screening criteria for a Pattern of Violations (POV), one of the toughest enforcement tools used. The announcement follows MSHA’s most recent screening, covering the period from Feb. 1, 2019, to Jan. 31, 2020.

This was the sixth consecutive screening that resulted in no POV notices. The last screening covered the period from Sept. 1, 2018, to Aug. 31, 2019. Under MSHA regulations, MSHA conducts POV screenings “at least once each year.”

MSHA reserves use of the POV provision – established in the Federal Mine Safety and Health Act of 1977 – for mines that pose the greatest risk to miners’ health and safety, particularly those with chronic violation records.

“Safety and health is what we care about most at the Mine Safety and Health Administration. It’s what miners care about, it’s what miners’ families care about and we can see it’s what mine operators care about,” said MSHA Assistant Secretary David G. Zatezalo. “We’ll issue Pattern of Violations notices when we need to, but it’s a good feeling to look at the screenings and see no mines meeting the criteria.”

In January 2013, MSHA published its POV rule to strengthen safety measures in the nation’s most dangerous mines. Under the regulation, MSHA may consider mitigating circumstances before issuing a POV notice and encourages mine operators to implement a corrective action program if they are close to meeting the POV screening criteria.

MSHA provides two online tools to help mine operators monitor compliance: the POV tool, which informs mine operators how they rate against the screening criteria and should take appropriate corrective actions; and the S&S rate calculator, which enables mine operators to monitor their “significant and substantial” violations. Between 2011 and 2019, the rate of significant and substantial violations dropped from approximately 32% to 20%, an indicator of safety improvements in mines.

MSHA works to prevent death, illness and injury from mining, and promote safe and healthful workplaces for U.S miners. MSHA carries out the provision of the Mine Act as amended by the Mine Improvement and New Emergency Response Act of 2006. The agency develops and enforces safety and health rules for all U.S. mines regardless of size or number of employees. MSHA also provides technical, educational and other types of assistance to mine operators. MSHA works cooperatively with industry, labor, and other federal and state agencies to improve safety and health conditions for all miners.

COVID-19

MSHA has received a high volume of questions regarding the coronavirus/COVID-19 and both mine operator actions and MSHA actions in response. The following information provides practices for operators and miners to minimize the spread of coronavirus/COVID-19 and actions MSHA is taking to do the same.

What Should Mine Operators and Miners Do?

- Avoid close contact: Put distance between yourself and other people (about 6 ft.) This includes not crowding personnel carriers, hoists and elevators, or other means of transportation at the mine.

- Clean and disinfect: Wipe down equipment and other frequently touched surfaces.

- Wash hands: If soap and water are not readily available, use a hand sanitizer that contains at least 60% alcohol. Cover all surfaces of your hands and rub them together until they feel dry. Avoid touching your face, nose, eyes, etc.

- Stay at home if you are sick.

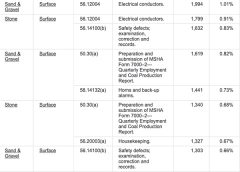

| The Dirty Dozen: 12 Most Frequently Cited Standards (2019) |

|

|

What Actions Is MSHA Taking?

- MSHA is abiding by the president’s Coronavirus Guidelines for America, which are based on the “CDC Interim Guidance for Risk Assessment and Public Health Management of Persons with Potential Coronavirus Disease 2019,” which covers, “Workers who support the operation, inspection and maintenance of essential public works facilities and operations, including bridges, water and sewer main breaks, fleet maintenance personnel, construction of critical or strategic infrastructure, traffic signal maintenance, emergency location services for buried utilities, maintenance of digital systems infrastructure supporting public works operations, and other emergent issues.”

- MSHA will continue to perform its essential functions, including mandatory inspections, serious accident investigations, and investigations of hazard complaints (imminent danger or serious in nature).

- For the pendency of the president’s national emergency declaration, MSHA has suspended Educational Field and Small Mine Services visits, as well as special safety and fatality initiatives that normally would gather groups of miners on-site to discuss powered haulage, electrocution, and contractor safety.

- To the extent feasible, inspectors are maintaining distance from miners while performing inspections.

- MSHA will work with mine operators when it comes to the following recertifications:

– Annual refresher training certification (30 CFR Part 46).

– Surface and underground annual refresher training certification (30 CFR Part 48).

– Certified person; sampling (30 CFR §§ 70/71/90.202).

– Certified person; maintenance and calibration (30 CFR §§ 70/71/90.203).

Exemptions to recertifications will not be granted; however, their due dates will be extended by at least the time the government is operating under the president’s emergency declaration. Please note: This exception does not apply to new miner training. New miners must be trained before beginning work. Once the Emergency Declaration is lifted, mine operators should work with their respective district offices to ensure that all certifications are conducted in a timely manner.

- MSHA supports operators’ efforts to minimize the spread of the coronavirus/COVID-19, including screenings or questionnaires, and will encourage our inspectors to participate on a voluntary basis.

- MSHA is following all protocols for identifying MSHA inspectors or other employees exhibiting symptoms or who have had potential exposure, asking them to quarantine at home, and cleaning the relevant offices following CDC guidelines.

- MSHA recognizes that some mining operations are not running at full capacity and have limited crews working. If a mine operator alerts MSHA to changes in production at a site, MSHA will, to the extent possible, limit the number of inspectors sent to that mine for a regular inspection proportional with the mine’s continuing operations.

If you have questions regarding MSHA requirements, including reporting, certifications or plan submissions, or updates on the status of your operations and staff on-site, please contact the appropriate MSHA District Office, which can be found at www.msha.gov/about/program-areas/mine-safety-and-health-enforcement.

Many state and local governments have issued emergency orders imposing closure and shelter-in-place restrictions for citizens and businesses. MSHA does not have jurisdiction to enforce or implement these emergency orders. If you have concerns regarding state and local emergency orders or compliance with those emergency orders, please contact the appropriate state or local government office.

Fatalities

There were 24 mining fatalities in 2019, MSHA reported. This is the fewest annual fatalities ever recorded, and only the fifth year in MSHA’s 43-year history that mining fatalities were below 30. MSHA is still reviewing two cases of possible chargeable fatalities which, if added would make the total in 2019 the second lowest number of fatalities ever recorded.

There were four deaths each in Kentucky and West Virginia; two each in Pennsylvania, Tennessee and Texas; and one each in Georgia, Idaho, Illinois, Louisiana, Minnesota, Mississippi, New Mexico, Oklahoma, South Carolina and Vermont.

“The low number of mining deaths last year demonstrates that mine operators have become more proactive in eliminating safety hazards. But I believe we can do even better,” said Assistant Secretary David G. Zatezalo. “A disproportionate number of mining deaths involved contractors, and we saw an uptick in electrocution accidents, with three deaths and another two close calls. In response, the Mine Safety and Health Administration launched a targeted compliance assistance effort, visiting thousands of mines to educate miners, operators and contractors on procedures that could prevent accidents like these.”

MSHA has reported the following fatalities for 2020:

June 13, 2020, Fatality

Accident Classification: Machinery

Location: Fast Pak Crusher, Maricopa, Ariz.

Mine Controller: Salt River Pima-Maricopa Indian Community

Mine Type: Surface

Mined Material: Construction Sand and Gravel

June 1, 2020, Fatality

Accident Classification: Slip or Fall of Person

Location: Plant 1, Maricopa, Ariz.

Mine Controller: Gary Curtis

Mine Type: Surface

Mined Material: Construction Sand and Gravel

May 2, 2020, Fatality

Accident Classification: Handling Material

Location: Enon Sand &Gravel, Clark, Ohio

Mine Controller: James P JurgensenII; Jacqueline J Alf; Jason R

Mine Type: Surface

Mined Material: Construction Sand and Gravel

Feb. 29, 2020, Fatality

Accident Classification: Machinery

Location: Newark Aquisition, LLC, Beauregard, La.

Mine Controller: Mark LaBorde; Kevin A Cook

Mine Type: Surface

Mined Material: Sand, Common

Feb. 27, 2020, Fatality

Accident Classification: Handling Material

Location: Patterson Road, Allegan Mich.

Mine Controller: CRH PLC

Mine Type: Surface

Mined Material: Construction Sand and Gravel

Feb. 27, 2020, Fatality

Accident Classification: Powered Haulage

Location: Federal No 2, W. Va.

Mine Controller: Patriot Coal Corp.

Mined Material: Coal (Bituminous)

Feb. 10, 2020, Fatality

Accident Classification: Powered Haulage

Location: Brush Valley, Indiana Pa.

Mine Controller: J Clifford Forest III

Mine Type: Underground

Mined Material: Coal (Bituminous)

Jan. 23, 2020, Fatality

Accident Classification: Slip or Fall of Person

Location: Tehachapi Plant, Kern, Calif.

Mine Controller: Heidelberg Cement AG

Mine Type: Facility

Mined Material: Cement

Jan. 8, 2020, Fatality

Accident Classification: Slip or Fall of Person

Location: Portable Crushing Dept 415, Clinton County, Iowa

Mine Controller: Manaco Corp.

Mine Type: Surface

Mined Material: Crushed Broken Limestone NEC

Current Initiatives

Powered Haulage Safety Initiative

About half of all U.S. mining fatalities in recent years – including 13 of the 27 fatalities in 2018 – were due to accidents involving powered haulage. That classification includes mobile equipment, conveyor systems, and anything else under power that hauls people or materials. MSHA has made the prevention of powered haulage accidents a priority, with an initial focus on three areas: mobile equipment at surface mines, seat belt usage, and conveyor belt safety.

Mobile Surface Equipment

Surface mining vehicles can be several stories tall and are capable of destroying smaller vehicles that cannot be seen by the operator. Traffic controls, training, and avoiding distractions are key to enhancing safety. Collision warning and avoidance systems can also help.

Seat Belt Usage

MSHA engineers estimate that three to four miners’ lives could be saved each year if adequate seat belts were provided and worn. Warning systems such as chimes can remind drivers to buckle up, while interlock systems can prevent the vehicle from moving if the belt is unbuckled.

Conveyor Safety

Belt conveyors and their components pose serious risks to miners working on or around them. It’s important to install adequate guarding to prevent contact, provide and use crossovers and cross unders, and lock out energy sources and block motion whenever performing maintenance.