Rock Products’ Spring Product Roundup Focuses On The Equipment, Technology And Services Displayed At North America’s Largest Trade Show.

By Mark S. Kuhar and Josephine Patterson

Look for additional reports featuring equipment and technology seen at ConExpo-Con/Agg in upcoming issues of Rock Products. – Ed.

After five jam-packed days of innovative product launches and major company announcements, enlightening education sessions and countless networking opportunities, ConExpo-Con/Agg 2023 came to a close, but not before taking the construction and aggregates industries to the next level.

The show crushed expected attendance numbers, drawing more than 139,000 construction, aggregates and fluid power professionals from 133 countries to Las Vegas from March 14-18 – making it the largest trade show in North America with more than 2,400 exhibitors from 36 countries spread out over 3 million sq. ft. of exhibit space.

“The innovations in the construction industry unveiled this week will play a role in helping construction professionals drive meaningful and sustainable economic growth,” said Phil Kelliher, Caterpillar senior vice president and ConExpo-Con/Agg show chair. “Live events in the construction industry are very important, because you can see, touch and experience the products. That value was reaffirmed this past week across the show floor.”

This year’s show emphasized how the construction industry is evolving in many ways to adapt to sustainable technologies, products and practices. Show attendees were treated to sustainability in action, from electric and hydrogen powered construction equipment, to more recyclable materials and waste reduction opportunities.

Manufacturers Comment

Terex MPS showcased the exclusive new Cedarapids CRC1350S Portable Cone Crusher Plant and the new Simplicity ESX “Extra Clearance” Series Horizontal Screen: first-to-the-market models with features not offered by others in the industry.

“Our team was grateful for the opportunity to visit with so many people during the 2023 ConExpo-Con/Agg event,” said Russ Burns, sales director, Terex MPS. “The chance to showcase two new pieces of equipment and receive first-hand feedback from passionate people in our industry was very positive. Our team truly enjoyed visiting with the numerous loyal customers and visitors from around the world and getting a chance to hear the stories and share experiences with our legacy brands.”

McLanahan Corp. showcased, among other equipment, a Horizontal Screen Over Screw Portable Plant for the first time at any trade show. While this is not a new piece of equipment for McLanahan, it is a highly demanded configuration that the company’s dealers requested be on display due to its popularity.

“What a fantastic week to get back together and celebrate our industry,” said McLanahan’s Managing Director – North America Mark Krause. “After the last three years of video conferences, combined with a robust economy and optimistic outlook, the timing was perfect for face-to-face conversations about where our industry, and specifically our companies, are headed. It allowed us to see old friends, meet new clients and introduce some new products. I found that this show, more than previous ones, had buyers coming to the show to negotiate deals. We weren’t sure how traffic would flow with the new lots and the West Hall, but nothing appeared different than past shows. ConExpo-Con/Agg 2023 really set the tone for what should be a very exciting year.”

Superior Industries Inc. showcased more than 250-tons of its products at ConExpo-Con/Agg. At least eight of the products were brand-new and revealed for the first time at the show.

“Honestly, it was one of the best trade shows we’ve ever attended and we’re not just blowing smoke,” said Corey Poppe, communications manager. “The crowds were large, their energy was high and the reaction to our new products was very positive As sales now follows up, our marketing team is already dreaming about 2026.”

BKT displayed it’s EARTHMAX tire line such as the BKT EARTHMAX All-Steel radial tires, designed to withstand the harshest conditions. Watch video from their booth.

“Attending the ConExpo show is always a must for BKT, and this year was no different. We were able to meet with many key customers, partners, and potential customers from all over the world. Participating in the show is vital to our business in the United States and helps us stay competitive in the construction industry,” said Alexa Sherry, the company’s marketing and business analyst.

Showstopper

For the first time, Wirtgen Group shared a 70,000-sq.-ft. booth with John Deere and it was a showstopper. Exhibiting in production systems, specifically Aggregates, where equipment from Deere and Kleemann stood side by side, customers could see a unique supplier that can support an operation from material handling to crushing and screening, to loading. A one-stop manufacturer that supports the complete package for any producer.

“The atmosphere and energy at the booth were exhilarating, and to be back with our customers enjoying the business made it a truly unique trade show,” said Evan Clark, vice president of sales for Wirtgen. “Thanks to all our customers and dealers who visited with us and enjoyed our friendships and passion for the business.”

Van Der Graaf (VDG) is the leader in the design and manufacturing of drum motors for all types of belt conveyor applications, including mining and aggregate, ship loading and power generation. GrizzlyDrive Series Drum Motors are designed specifically to operate in harsh, dusty, abrasive and extreme environments where performance and durability matter most. Watch video from their booth.

“ConExpo-Con/Agg was a really good show for VDG,” said Alex Kanaris, company president. “We had extremely good traffic in our booth during the first three days and a very quiet last two days. The attendees stopping at our booth demos were really good. We had very good feedback from existing customers stopping by to share their positive experience with our products, and potential customers acknowledging seeing our ads and wanting to see the product up close. The show was busy, productive, efficient and well attended.”

Philippi-Hagenbuch highlighted HiVol Water Tanks, along with other custom-engineered off-highway haul truck solutions, at ConExpo-Con/Agg.

“2023 was my eighth ConExpo-Con/Agg as a member of the Philippi-Hagenbuch team,” said Josh Swank, vice president of sales and marketing for the company. “Looking back on the show now after a couple of weeks, I still feel the excitement – and maybe a bit of the lasting exhaustion from all of the excitement and hard work leading up to it – from another truly outstanding ConExpo-Con/Agg. Philippi-Hagenbuch’s booth in the new West Hall became the site of more than 400 daily meetings between our team members and attendees, with more than 20,000 other people spending time in or around our booth each day. Beyond the sheer numbers, the attendees we interacted with were individuals who expressed genuine interest in discovering new products and technology to drive productivity and efficiency for their operations back home.

“Beyond the show floor, I had the opportunity to attend the National Stone, Sand & Gravel Association (NSSGA) Annual Convention where I passed on the gavel to the incoming chair of the Manufacturing & Services Division Executive Committee, Charlie Johnson,” Swank continued. “Additionally, I was fortunate to be able to present an educational seminar, ‘Improve Efficiency with Haul Truck Customizations,’ on Thursday morning as part of the ConExpo-Con/Agg educational track. Once again, I was thrilled by the genuine interest that the attendees showed and the number of thoughtful questions and discussion that resulted.”

Signature Products

MAJOR highlighted its FLEX-MAT Modular PLUS screen media panels at ConExpo-Con/Agg. Watch video from their booth.

“The much-anticipated ConExpo-Con/Agg 2023 came and went faster than we could imagine. After months of preparation, it was exciting to see our hard work pay off and have invaluable meetings face-to-face with new and current customers, as well as our dealers,” said Ian Edwards, senior director for global sales at MAJOR. “Plus, its record-breaking attendance reaffirmed why events like this one are so important. With the increased demand for raw materials, we were proud to highlight our efficiency-enhancing range of screen media, including our FLEX-MAT Tensioned screens, FLEX-MAT Modular screens and Woven screens, among other products.

“Our signature FLEX-MAT screen media is uniquely designed to combine high open area and efficient stratification to prevent blinding and pegging throughout the screening process,” Edwards said. “While often overlooked, the profitability of the plant depends on proper screen media selection. With this in mind, we – alongside our dealers – strive to work closely with our customers to understand the ins and outs of their operation to ensure they are equipped with the appropriate screen media to maximize production.”

Preparing for ConExpo-Con/Agg is a marathon where you cross the finish line at 9:00 a.m. on Tuesday morning as attendees flood through the gates, remarked Kristen Randall, global technology marketing manager at Haver & Boecker Niagara.

“We had many opportunities at the show to meet with new and current customers, introduce new technology – including multiple deck frame upgrades and our full Pulse diagnostics suite – and had fun along the way by celebrating our company’s German heritage with customers at our daily Oktoberfest event,” she said.

“Almost 140,000 attendees certainly beats the previous show. We had heard rumblings that attendance was high, but that’s a major increase,” Randall continued. “What a fantastic surprise. It goes to show the dedication towards growth and new technology, and the importance of camaraderie within the aggregates industry.

“Thanks to the fantastic turnout, our team has been working on several new projects and is looking forward to promising results for our customers in 2023. And, we are looking forward to ConExpo-Con/Agg 2026,” Randall concluded.

Anaconda Equipment

Over the years Anaconda Equipment has proven itself as a reliable partner in the crushing and screening industry. The most recent addition to the crushing division is the all-new Anaconda I12- Rv3 Impact Crusher. The I12-Rv3 is the culmination of possibilities when engaging with dealers and end users to determine the features and specifications required for the market.

The I12-Rv3 is a mid-sized impact crusher designed to offer operators and contractors excellent reduction of the initial feed material, continuous production and with a consistent product shape. Designed predominately for quarrying and recycling applications this versatile crusher fabricated with a 43-in. (1,090 mm) diameter 4-bar rotor on a 45-in. (1,140 mm) wide Universal Crushers Impact Chamber will make light work of any application.

The I12-Rv3 is fitted with a large hopper area and an aggressive vibrating pan feeder with a two-tier grizzly section to help facilitate the movement of the feed material towards the Impact Chamber. The grizzly section allows for fines and smaller dirt to be eliminated from entering the chamber by discharging it onto the side dirt conveyor or directly onto the main conveyor. There is also an underpan option that transfers material from the chamber to the main conveyor, this is used in recycling applications to stop rebar from causing damage to the main conveyors belt. Anaconda, www.anacondaequipment.com

Astec Industries

For its aggregates customers, Astec Industries’ Materials Solutions Group designed and launched its newest portable high-frequency screen plant, the PTSC2818VM for display at ConExpo-Con/Agg. The plant’s innovative design and size is the first of its kind for the industry, featuring an 8-ft.-wide high frequency screen.

Astec’s newest PTSC plant is equipped with an 8- x 18-ft. (2.4- x 5.5-m) top deck and an 8- x 12-ft. (2.4- x 3.- m) bottom deck. The patent-pending screen design features externally mounted vibrators at the ends of the tappets for a more aggressive screening action.

This unique design creates a higher G-force and reduces heat load from material to motors as compared to single, center-mounted vibrators. It also allows for easier maintenance and adjustments. The screen is equipped with hydraulic operating angle adjustment, a fines collection hopper, top- and bottom-deck discharge chutes and an aggregate spreader. Astec Industries, www.astecindustries.com

CASE

CASE Construction Equipment put the construction industry on notice with a promise that “You’ll See the Difference” at ConExpo-Con/Agg. The more than 180-year-old manufacturer highlighted “The New CASE” at the industry’s largest North American trade show – showcasing groundbreaking new equipment, exciting new partnerships and a range of new solutions designed to help contractors get more work done, easier and more profitably than ever before.

“A focus on innovation is extremely important but it isn’t enough to support our industry in 2023 – our dealer network, our equipment, and our team will build on our legacy and turn heads as we make moves to greatly enhance equipment users’ productivity,” said Terry Dolan, vice president – North America, CASE Construction Equipment. “At ConExpo-Con/Agg, CASE launched exciting new machines, revealed some unexpected products and our booth clearly demonstrated our plan for making work easier and more productive.”

“All great companies and great brands evolve,” said Rebecca Bortner, director of marketing, CASE Construction Equipment. “‘The New CASE’ marks the next step in our evolution as a brand and we’re looking forward to making some waves in the industry.”

The CASE booth showcased industry and business solutions to make contractors’ jobs easier – this includes more than 30 new machines, tons of new attachments, ingenious new technology and educational sessions with tips on best practices around technology, equipment, fleet management and more. “2023 will be a year where we reshape the industry and help businesses and equipment owners do better in all facets of their work,” concluded Dolan. “ConExpo-Con/Agg is just the start.” CASE, CaseCE.com/SeetheDifference

CDE

CDE, a supplier of sand and aggregate-washing solutions for the waste recycling and natural processing sectors, revealed plans to commission multiple new waste recycling plants across the Americas following a successful ConExpo-Con/Agg.

At this year’s show, CDE showcased the top-of-the-range solutions that underpin its recycling process, including the latest generations of its AggMax scrubbing and attrition system; Counter Flow Classification Unit (CFCU) for density separation; ShearClean attrition cells and EvoWash sand classification and dewatering plant; and launched the latest addition to its range of Infinity high-frequency dewatering screens.

The washing experts welcomed existing customers from across the region to share their experiences of materials washing and the CDE recycling process, which served as the backdrop for multiple new deals struck at the show.

Set to be commissioned within the next year, the deals include new wash plants for customers based in the United States, Canada and Latin America, with more than 50% representing waste recycling operations and underscoring CDE’s commitment to accelerate the adoption of sustainable technologies in the industry.

Among the customers who shared their experiences of the CDE process at the show was Our Recycling Corp. Operating for more than 30 years, Our Recycling Corp. began crushing concrete in the early to mid-1990s to reduce the costs of bringing crushed natural stone from Connecticut to New York.

“It’s been great partnering with Our Recycling Corp., and I believe we’ve built a relationship to last. This was evident when Todd shared his CDE story with guests at ConExpo-Con/Agg,” said CDE Director Darren Eastwood. “The resulting solution represents our commitment to pursue a circular economy, facilitating the diversion of vast tonnages of material from landfill, transforming them into high-grade recycled sand and aggregates for the construction industry, while simultaneously restoring land for future use and driving down carbon emissions.”

The 250-tph solution designed and engineered by CDE comprises of a M2500 modular washing plant, Infinity screen P2-75 and AquaCycle A400 thickener, water management system, which create market ready sand and aggregates. CDE, www.cdegroup.com

Caterpillar

Delivering premium performance, the new Cat 950 and 962 Next Generation Wheel Loaders feature standard simple-to-use technologies that boost operator efficiencies, provide consistent bucket fill factors and increase productivity by up to 10% over the previous models. These flexible loaders offer application-specific designs to excel in the toughest applications, while service intervals are extended to lower maintenance costs by up to 30%.

Their field-proven, reliable Cat C7.1 engine offers high power density with a combination of proven electronics, fuel and air systems. Equipped with the automatic Cat regeneration system, the engine meets U.S. EPA Tier 4 Final, EU Stage V, Korea Tier 5 and Japan 2014 emission standards without interrupting operation. Electric fuel priming pump, fuel-water separator and secondary fuel filter combine with component design and machine validation to offer unmatched reliability and uptime.

A range of standard technologies on the 950 and 962 wheel loaders efficiently monitor, manage and enhance jobsite operations. Providing accurate weighing of material, Cat Payload with Assist displays data in real time to improve productivity and loading efficiency. The operator can now fully automate bucket loading using new Autodig to improve fill factors and loading times. Working in combination with Autodig, new Auto Set Tires promotes proper loading technique to significantly reduce tire slip and wear.

New application profiles give operators the ability to set customized profiles for customer-specific applications at the touch of a button to optimize loader settings for the job. Facilitating loader operation, selectable job aids allow operators of all experience levels to be more productive. Wirelessly connecting the machine to the office, Product Link gives access to production and essential machine health information for making fact-based decisions.

Loader and operation productivity are further enhanced with optional Cat technologies. Available Cat Advanced Payload with Assist includes Tip Off Assist to automate load adjustment of the final bucket to match target. Plus, its enhanced lists management, site integration and extended scale features help manage and improve productivity. Also helping to improve profitability of operations, the optional Cat Productivity subscription provides detailed and comprehensive actionable information. Caterpillar, www.cat.com

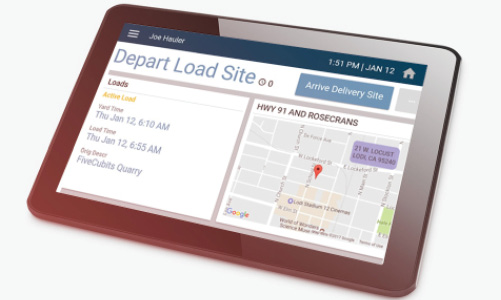

Command Alkon

Command Alkon offers industry-specific hardware and software systems for producers, suppliers and haulers of ready-mixed concrete, concrete products, aggregate, asphalt and cement. The Command Alkon’s family of products displayed at the show addressed batching, dispatching, dispatch optimization, fleet and workforce management, quality control, bulk materials distribution, plant and quarry automation, transportation planning and performance, process controls, back-office operations, performance management, enterprise content management, voice-based scheduling and mobile computing.

Here are some descriptions of its focus products seen at the show:

- Dispatch – Cloud-based dispatch offers centralized management of all plant data and pricing and a consolidated view of total customer demand and operational capacity each day. Extend real-time information and communications with customers and field personnel and speed up invoicing and payment cycles.

- Inventory and Replenishment – Remove spreadsheets and phone calls from your inventory management playbook and capture a new level of visibility to manage your day and plan the next day with ease. Automatically forecast inventory needs, place vendor orders, and replenish inventory based on scheduled daily orders.

- Customer Portal – Customer Portal offers delivery and order tracking for material suppliers and their customers. This cloud-based, mobile solution provides a convenient online experience for creating, managing, and tracking orders 24 hours a day.

- COMMANDassurance – Sensor data – including slump, temperature, volume, water additions, W/C ratio, drum rotation, and direction for each load – goes into the cloud and is readily available in real time to all who need it. Soon, measuring air-content in real-time will be available, giving complete and unparalleled visibility into concrete properties.

Command Alkon, www.commandalkon.com

Deister Machine Co.

With rising production costs and rigid specifications, it takes heavy-duty vibrating equipment to meet the challenge – big-capacity, cost-cutting, hard-working Deister screens and feeders – customized to fit the application. Ruggedly built and requiring minimal maintenance, Deister screens and feeders deliver dependable production even under the most adverse operating conditions or when handling the most abrasive materials.

Deister engineers talked with producers about specific screening and feeding solutions at ConExpo-Con/Agg. Attendees received an up-close look Deister’s extra heavy-duty triple-deck inclined vibrating screen – and its heavy-duty horizontal triple-shaft vibrating screen.

Since 1912, the family owned Deister Machine Co. has been recognized for building innovative vibrating screens with superior quality. Its heavy-duty equipment ensures reliable day-to-day performance. Units are designed with extra protection at all vital points, and extra-heavy duty bracing and frame members that ensure long vibrating frame life.

Deister engineers ensure that every screen and feeder is designed to deliver greater efficiency while lowering operating costs-per-ton. Deister equipment is American-made and backed with 24/7 parts and service support, and a dedicated dealer network. Deister Machine Co. Inc., www.deistermachine.com

John Deere/Wirtgen

Delivering purpose-built machines and technologies to customers around the globe, John Deere showcased a variety of productivity and sustainably focused construction solutions with alternative power options at ConExpo-Con/Agg 2023. These offerings provide customers an innovative and eco-friendly take on industry-trusted equipment.

“As we continue to introduce battery-electric and electric-hybrid solutions to the market, we aren’t just designing a new way to fuel your fleet. We’re also focusing on building an electric infrastructure through innovative and forward-thinking technology,” said Ryan Campbell, president, Worldwide Construction & Forestry and Power Systems. “That means expanding our efforts to provide customers with optimal dealer support, jobsite data and charging solutions aimed to increase the electric presence in the construction space around the world.”

John Deere will offer E-Power machines utilizing battery solutions from Kreisel Electric. Offering a hybrid solution, E-Drive machines feature an electrified drivetrain with an engine as the primary power source. In addition, E-Drive machines enable better fuel economy, improved powertrain component life and stronger pushing power on the job than traditional models.

The John Deere electrification/hybrid journey began in 2013 with the introduction of the 644K Hybrid wheel loader, which has since evolved into today’s 644 X-Tier. The 644 X-Tier is notable for its robust performance with its combined E-Drive and Power Shift transmission system.

In addition, the 944 X-Tier wheel loader is newly rebranded from the 944K Hybrid to align with the John Deere performance tiering strategy. With more than 3 million collective customer hours since entering the market, John Deere E-Drive machines are built on customer experience and field proven electric technology.

Other new E-Drive machines on display at the show were the 850 X-Tier dozer, which will accompany the 850 P-Tier model in the future. The 850 X-tier provides customers with multiple operating modes to tailor performance and fuel consumption to their specific jobsite needs. The less complex drivetrain powers each track with an electric motor to maintain the maneuverability and control of a traditional hydrostatic John Deere dozer. Lastly, the 744 X-Tier E-Drive wheel loader, featuring an electric variable transmission, provides improved performance with increased fuel efficiency.

In 2021, John Deere tested and showcased the 310 X-Tier E-Power electric backhoe. E-Power technology provides lower daily operating costs, lower jobsite noise, and zero tailpipe emissions. In 2023, the 310 X-Tier E-Power backhoe model will enter the next phase of development and will continue to improve as a result of customer feedback.

The 145 X-Tier E-Power excavator concept, previously showcased at the 2023 Consumer Electronics Show, was also on display. The battery electric 244 X-Tier compact wheel loader, which made its debut at ConExpo-Con/Agg, is an ideal solution for customers looking to reap the benefits of an E-Power machine in a variety of material handling applications.

John Deere said it is also developing electrification infrastructure solutions to address the energy replenishment challenges faced by battery electric vehicles in off-road production environments. A John Deere electrification ecosystem will offer a wide array of solutions to address needs for charging, data and connectivity, machine support, and financial services.

The charging ecosystem will include a range of solutions for overnight and fast charging. All John Deere machines and charging stations will use common automotive style charging connections, helping to simplify the re-charge process for electric equipment. In addition, John Deere is developing new features, such as an Operations Center specific to battery-electric equipment to help customers monitor usage remotely and manage work while charging their equipment with confidence and ease. Deere & Company, www.JohnDeere.com

Watch video from their outdoor display.

Develon

Develon, formerly known as Doosan construction equipment, demonstrated its commitment to the future of construction sites with updates to its Concept-X and XiteCloud smart construction platform during ConExpo-Con/Agg 2023.

Concept-X was unveiled in 2019 as the world’s first automated construction solution. At a demonstration of Concept-X in Korea, attendees witnessed autonomous construction equipment performing everyday jobsite tasks.

Develon unveiled the latest developments to the technology-based solution in an updated version called Concept-X2. The newest iteration of the solution includes the following updates:

- New dozer added to autonomous equipment lineup.

- Autonomous driving and blade control based on global navigation satellite system (GNSS).

- Automated 3D grading with tiltrotator accessory.

- Enhanced machine-learning-based auto digging and loading.

- Integrated work planning algorithm applied.

- Advanced E-Stop safety technology.

The Concept-X2 autonomous construction equipment in the Develon booth included the DD100-CX dozer and DX225-CX crawler excavator. Both machines feature a new cabinless design and a linear core design language..

As part of the innovation area of the Develon booth, the company promoted the latest developments of its all-in-one smart construction platform: XiteCloud.

With XiteCloud solutions, a customer can manage multiple tasks such as surveys, terrain analysis, machine purchases, equipment operation and construction management on a single platform, thereby reducing construction costs and saving time while increasing work accuracy, which in turn raises productivity. XiteCloud also allows customers to manage multiple projects on a single platform, accumulating and managing data that can be utilized for future decision making/business. Develon, https://na.develon-ce.com/en/develon

Durex Products

Durex Products Inc. displayed its screen media, liners, wear parts and screen accessories at ConExpo-Con/Agg. The company offers numerous innovative urethane, rubber, and wire screen media options, which allow customers to fine-tune production and increase tons per hour, while keeping products in spec and lowering operating costs.

Durex has offered premium screen media technologies since 1965, including its well-known Livewire, Armor, Accuslot, Vibraspan and Vibraclean wire screens and Urethane and Rubber screens. Wear liners for aggregate and concrete equipment, wear parts, and screen accessories round out the company’s offerings. Durex, durexproducts.com

Eagle Crusher Co.

Eagle Crusher Co. introduced two new plants at ConExpo-Con/Agg. The new UltraMax 1600X-OC Portable Impactor Plant is designed for larger-size aggregate operations and quarries. It features the UltraMax 69X Impactor with a 69-in. x 51-in. feed opening to allow larger material into the impactor to increase throughput, up to 1,000 tph. This means producers can prep less and crush more to reduce costs and increase profits. The plant’s massive, solid-steel, three-bar, sculptured rotor, weighs in in excess of 13 tons and crushes even the largest feed material in a single pass.

The new 8 x 20 Screen Plant with Integrated Feed Conveyor and Blending Gates is for producers that demand multi-product screening and can produce up to four products simultaneously, three with absolute sizing, or return the oversized product for further reduction. The integrated 60-in. feed conveyor remains on for transport and eliminates the need for a separate conveyor, while each screen deck features four blending gates to allow for a wide range of custom product mixes to meet specific product needs.

The 2036 Jaw Crusher is one of five jaw crusher models manufactured by Eagle Crusher. Like all the company’s jaw crushers, the 2036 is designed to eliminate premature failures and provide years of component life, durability and reliability. It processes abrasive hard rock, using the time tested overhead eccentric design. All moving parts are contained within the main housing, making it ideal for portable or skid mounting. Eagle Crusher Co., www.eaglecrusher.com

Eagle Iron Works

Eagle Iron Works has offered customers reliable, easy-to-operate equipment to handle washing and classifying applications since 1872. After celebrating 150 years of business in 2022, EIW has expanded its product line to show the industry that the company will continue meeting the demands of the industry for the next 150 years.

During ConExpo-Con/Agg, EIW highlighted the classic equipment for which it is known and also displayed a brand-new line of equipment that completes its already extensive list of washing equipment.

“EIW has been successful for the last 150 years because we design and build the heavy-duty equipment that the industry needs. We listened to the customers and industries around us and have developed a new system that we’re excited to launch,” said Tim Miller, business line director – EIW.

In addition to the launch of its new equipment, EIW showcased its Eagle genuine parts and gear reducer programs – all designed to ensure that your operation is always running with minimal downtime. EIW, www.eagleironworks.com

Epiroc

Epiroc stepped up to the plate with a range of its latest products. These include two new surface drill rigs that demonstrate new advances in the SmartROC series, two smart grouting systems, a new Down-The-Hole (DTH) hammer, a new V-shaped drum cutter, new digital tools and related aftermarket solutions.

All of these products have been designed to help accelerate the transformation of the construction industry to become more sustainable, efficient and environmentally friendly.

The SmartROC T25 R is a radio-remote rig built on a new platform and offers several valuable features, all of which will be showcased as part of the rig’s pre-launch. These include an exceptional coverage area, excellent “terrainability” and application versatility – all backed up by a smart Rig Control System (RCS) and future-proof digital functions that improve efficiency and help to reduce the rigs’ climate impact through fuel savings.

The upgraded version of the advanced SmartROC T40 tophammer rig for quarrying and construction consumes less diesel than any other diesel-hydraulic rig in its class and offers superior performance even under the toughest drilling conditions. The rig’s class-leading fuel efficiency reduces environmental impact and costs. It also comes with smart features and options that boost productivity, including enhanced automation which helps to increase both drilling consistency and output.

The DTH 5 hammer represents a significant upgrade that gives more drilled meters per shift and the versatility needed to tackle any type of rock and task. The design offers 12 configurations and a 5% higher penetration rate compared to its predecessor and lasts approximately 10% longer. For the operator this translates into more productive and profitable workdays with fewer time-consuming and heavy changes of tools.

In January, Epiroc also launched new DTH drill bits which signals a new era for Down-The-Hole drilling. Thanks to a new design and the use of the new Epiroc carbide, these bits improve productivity and profitability while ensuring better workdays for operators Epiroc, www.epiroc.com

Haver & Boecker Niagara

Haver & Boecker Niagara highlighted its Pulse Condition Monitoring technology, along with other innovative mineral processing products and services, during ConExpo-Con/Agg. The technology is designed to monitor the health of vibrating screens using modern algorithms and artificial intelligence. It provides accurate measurements and forecasts complemented by information that is easy to understand. Pulse CM is a wireless diagnostics tool that helps mineral processing operations be proactive, rather than reactive, when it comes to maintenance efforts. This leads to increased efficiency, decreased downtime and improved reliability.

“Haver & Boecker Niagara has a history of developing solutions to help producers increase their uptime,” said Thiago Buoso, Haver & Boecker Niagara project and sales engineer. “Unexpected downtime is a huge source of lost revenue for producers, so we aim to create products and technology that prevent that. Additionally, there is a lack of reliable systems like this on the market. Pulse Condition Monitoring is the most detailed, accurate monitoring system available to customers.”

Pulse Condition Monitoring is one level of the Pulse portfolio, accompanying the company’s Pulse Vibration Analysis and Pulse Impact Testing. Similar to Pulse Vibration Analysis, the Pulse CM system analyzes data to help users get the most out of their equipment. Unlike Pulse Vibration Analysis, Pulse CM uses permanently installed sensors to monitor equipment 24/7. Haver & Boecker Niagara, www.haverniagara.com

Hitachi

At a special ConExpo-Con/Agg press event, Hitachi’s Vice President of Sales Simon Wilson described the company’s journey to the show. He said that almost 3,000 engineers have been working over the last year in Japan to develop new products for the market.

“The new Dash-7 machines will be introduced, and we have the complete lineup here either at our outside booth on the festival grounds or at our inside booth,” he said. “The excavators, from 13-ton all the way up to the 89-ton construction-size excavators are all new from the ground up. On the wheel loader side, you’ll see the new Dash-7 wheel loaders. A new look, a new design … customer feedback over the last year that has really validated the product, the packaging, and making sure that it fits what those customers are looking for.”

The company also focused on mining excavators from 120-ton up to the 800-metric-ton excavator. “Some of these are electric machines as well,” Simon said. “For the last almost 20 years, Hitachi has been providing electric machines to the mining segment. This is a very key area for decarbonization of the global mining business. The mining segment is a clear leader in this – in this shovel size up to these 800-metric-ton machines. Look for information as we introduce new haul truck technology [informed by] customer engagement. Some of the new sales and first sales in North America [have been] of these machines within one year of launch; we’re very proud as we introduce this.” Hitachi, www.hitachicm.us

Kleemann

With five mobile crushing and screening plants and the operating concept SPECTIVE, Kleemann presented a wide-ranging selection from its extensive product portfolio at ConExpo-Con/Agg. No less than three plants celebrated their premieres in North America.

The new MOBISCREEN MSS 802i EVO was presented to the general public for the first time in the United States. The powerful mobile screen for coarse elements was designed to meet changing challenges in different application areas.

With its clever plant design and flexible conversion options, it guarantees an optimum material flow in natural stone and recycling applications. The large range of screen surfaces and the simple setting of screening parameters make it possible to adapt the MSS 802i EVO easily to new application conditions.

If a fine final product is to be screened from particularly coarse feed material, the plant can be quickly converted from three to two final grain sizes. Further advantages of the plant include its simple operability thanks to its intuitive control, ease of physical and visual access to all relevant machine components and its drive concept H-DRIVE with the option of an external power supply for emission-free and therefore environmentally sound work.

The plants in the EVO2 generation demonstrate that output, efficiency and flexibility belong together. The latest members of the product line – the jaw crusher MOBICAT MC 110i EVO2 and the cone crusher MOBICONE MCO 90i EVO2 – were presented together as trade fair premieres at the show. Both plants have the efficient drive concept D-DRIVE and intelligent overload systems. Operation is simple thanks to SPECTIVE and SPECTIVE CONNECT.

The EVO2 line also includes the mobile impact crusher MOBIREX MR 110i EVO2. The plant impresses with flexible application options in both natural stone and recycling. The SPECTIVE operating concept ensures simple, intuitive control. The new feature here is that SPECTIVE CONNECT is now also available.

To further increase the application diversity of the MOBICONE MCO 90(i) EVO2 and MOBIREX MR 110(i) EVO2, both machines can now be equipped with an optional double-deck post screening unit and thus produce two classified final grain sizes without the use of an additional screening plant.

The innovative operating concept SPECTIVE includes various components that are ideally tuned to one another and accompany the machine operator during the entire working day. Apart from the intuitive touch panel and different radio remote controls, the digital application SPECTIVE CONNECT, above all, supports the work site digitalization. All relevant process information and reporting are now displayed on your smartphone without having to leave the feeding device.

SPECTIVE CONNECT has new features, which were presented in Las Vegas and which make work for the operator even easier. A new configuration tool, for example, supports in the selection of correct machine settings. The clever line coupling allows Kleemann plants to be easily coupled with one another.

Apart from the optimized material transport in all crushing stages, the new wireless line coupling guarantees safety. If an emergency stop button on the plant train is pressed in the event of an emergency, all machines are safely stopped. On crushing plants that are equipped with SPECTIVE, this is carried out via radio and cable installation is no longer required. This facilitates handling and makes the daily work routine of the operator easier. The Wirtgen Group (Kleemann), www.wirtgen-group.com

Komatsu

To help customers reduce their carbon footprint and plan for implementing sustainable solutions through electrification, at ConExpo-Con/Agg 2023 Komatsu featured its 20-ton PC210LCE electric excavator.

First displayed last fall at bauma, the PC210LCE was created for construction businesses that need a high-performance machine while cutting fuel costs. Featuring lithium-ion battery technology developed by Proterra, the excavator has 451 kWh of battery capacity, designed for up to eight hours of operating time.

Designed to reduce operator fatigue with less noise, exhaust emissions and zero engine vibration, the PC210LCE is ideal for use in urban areas and indoor environments. The low operating noise levels of the PC210LCE can allow for nighttime construction work both indoors and out.

Coming soon to North America, the PC210LCE supports Komatsu’s global sustainability targets of 50% reduction in CO2 emissions by 2030 and complete carbon neutrality by 2050. Komatsu is committed to helping customers manage energy transitions and increase efficiencies to help reduce fuel burn and emissions.

At the show, the PC210LCE was displayed with Smart Construction Retrofit, an affordable guidance kit that gives operators in the field and managers in the office access to both 2D and 3D design and payload data to help drive accuracy, control load volumes and improve operations. Easily installed by a local Komatsu distributor, this technology upgrade is designed to improve grading performance and help drive productivity and profitability. Komatsu, www.komatsu.com

Liebherr USA Co.

Liebherr presented the TA 230 Litronic, a representative of the new generation of articulated dump trucks, at ConExpo-Con/Agg 2023. The new TA 230 has been redeveloped based on comprehensive market research and customer feedback, featuring state-of-the-art technology.

This model has been tested to the limits through extensive evaluation phases to meet the highest quality standards. The result: An excellent product with a new design, which presents maximum quality and reliability. It offers optimum performance and efficiency and provides the utmost comfort.

The extremely robust, powerful and all-terrain machine is primarily designed for heavy hauling and rugged off-road use. The articulated dump trucks are also a useful assistant for larger infrastructure projects. Due to their optimal structure gauge, they can also be used for special applications, such as tunnel construction.

The TA 230 Litronic is designed with customers in mind and developed for various off-road applications. A new design for the front-end providing a large, sloped angle creates maximum ground clearance for superior off-road performance. The powershift transmission of the TA 230 Litronic is positioned safely and compactly under the operator’s cab, and the exhaust gas aftertreatment is safely installed behind the operator’s cab in a space-saving manner.

The newly designed, solid articulated swivel joint creates excellent off-road capability allowing independent movements of the front and rear, thus ensuring maximum maneuverability. The strong swivel joint with tapered roller bearing is perfect for the sheer stresses that arise during use, withstands maximum loads and provides optimal force distribution. For maximum ground clearance, the TA230 has front axle suspension with A-rods and shock absorbers at the articulated swivel joint and separate and oscillating A-rods on the rear axles.

A powerful six-cylinder engine with a displacement of 732 cu. in. (12 liters) and 355 hp (265 kW) comes standard in the TA 230 Litronic and is Tier 4F compliant. A robust and powerful drivetrain with automatic eight-speed powershift transmission ensures optimal force distribution. With the actively controlled longitudinal differential locks, automatic traction control is also available for the TA 230 Litronic. As soon as a slip occurs at an axle, the torque is transferred to the axle or axles with traction. The Liebherr articulated truck offers excellent driving performance and pulling force, even on the most challenging terrain. Maximum safety is ensured due to excellent road adhesion. Liebherr USA Co., www.liebherr.com

McLanahan Corp.

McLanahan Corp. has for many years offered customers field-proven, easy-to operate equipment mounted on portable chassis to handle washing and classifying applications to meet customer requirements. McLanahan, for the first time, brought its Portable Horizontal Screen Over Screw Plant to ConExpo-Con/Agg for its customers and dealers to see up close.

While this is not a new piece of equipment for McLanahan, it is a highly demanded configuration that the company’s dealers requested be on display due to its popularity. This configuration can be hauled using a semi-truck, showing the simplicity of setup at any operation, as well as the convenience of easy transportation between sites.

This portable plant features all McLanahan designed and manufactured major equipment pieces, which means customers are getting the same field-proven, heavy-duty equipment that is often used in stationary set ups in a compact, portable unit. It contains a horizontal screen and a double screw washer.

This plant includes the industry recognized McLanahan triple shaft horizontal vibrating triple-deck screen, which is able to size washed rock products for direct stockpiling. Built over a McLanahan Double Screw Fine Material Washer, this plant can size and wash three aggregate products and one sand product.

If your site is looking to produce aggregates to specifications using a highly compact, quick to set up, and easily moved unit, this portable unit has what you need. Being able to move quickly from site to site means more time operating, which increases your productivity and dollar in your pocket.

Based on years of experience with portable plants, all McLanahan Portable Solutions meet Department of Transportation standard to be easily transported. With a complete product range, an experienced process team, and a strong, local dealer network, McLanahan is committed to giving its customers solutions that are going to maximize their production and profitability. McLanahan Corp., www.mclanahan.com

Metso Outotec

As a result of continuing cone crusher technology development, Metso Outotec introduced a new HP200e cone crusher to the aggregates market, providing more performance and uptime in a more sustainable way, enabled by kinematics and new chamber designs.

The new liners are fitted in the crushers without backing material, making maintenance breaks shorter and the liner replacement faster, safer and less hazardous for the environment.

”The evolution of Metso Outotec’s cone crusher technology brings multiple benefits and present a true evolution for aggregates producers in terms of performance, uptime, serviceability and application coverage,” said Ilkka Somero, product manager, Nordberg HP Cone Crushers in Metso Outotec. “The concrete benefits include enhanced performance, +10% more head motion, +20% more kW power, +20% more force, new more efficient chambers, an anti-spin brake for higher uptime, serviceability improvements and a feed cone lifting tool. Environmentally, the new HP200e crushers are also a more friendly solution, as they do not require backing material. We are truly happy to be able to offer this latest evolution of our leading crusher technology to our customers.”

Metso Outotec ensures strong aftermarket support and availability for the HP200e crushers. The majority of spare parts in the current HP200 and the new HP200e are common, which will enable continued global spare part support for new units. Metso Outotec has established a start-up inventory for HP200e specific parts in Europe and North America.

Further, a full scope of HP200e crushing chambers will be available in main stocking locations for the launch markets. Metso Outotec also provides a head and bowl upgrade kit for the existing HP200 cone crushers, allowing the installation of no-backing chambers and for customers to enjoy the same health, safety and environmental benefits as with the new HP200e model. Metso-Outotec, www.mogroup.com

Montabert

With Montabert’s recent acquisition of Tramac – a manufacturer of rock breaker boom systems and a long-time distributor of Montabert breakers branded under the Tramac name – the company has expanded its quality product offerings for aggregate producers.

Tramac offers nine models of stationary boom assemblies for rock breakers that – depending on the model – provide horizontal reach from 14 to 65 ft. (4.3 to 20 meters), 170 to 360 degrees of swing arc and 1,500 to 13,000 ft.-lb. of hammer impact. Boom weights range from 5,850 to 55,000 lb. (2,650 to 24,950 kg) and accommodate hammer weights from 1,098 to 9,920 lb. (498 to 4,500 kg).

Standard across its entire boom line, rugged cylinders of high-strength steel and welded construction are built from chrome-plated, high-tensile steel rods. Heavy-duty, oversize pins are fitted with replaceable aluminum bronze bushings. Self-aligning spherical bushings on the cylinder rod and barrel end ensure long equipment life. An extremely strong, low-profile base of shaped plate steel attaches easily to any platform foundation. Tramac also offers a number of boom, HPU, hammer, and control options, as well as custom design services.

Montabert’s complete line of rock breakers for stationary and mobile systems include:

Premium Heavy Breakers: Montabert Premium Heavy Breakers are designed for all types of carriers, from 18 to 120 tons, and are ideal for a variety of applications, including quarrying, mining, excavation, and demolition. Features and benefits include:

- Automatic variable-speed technology senses changes in material hardness and adjusts impact energy and striking rate. This increases productivity, based on the application, and reduces blank firing. The technology also reduces unnecessary harmful energy from transferring to the carrier and breaker, helping to prevent wear on parts and components.

- Energy chamber acts as a hydraulic shock absorber and reduces pressure variations in the hydraulic circuits to provide consistent energy to the breaker – reducing pressure spikes and keeping the charge constant, with no periodic maintenance required.

- Progressive start system prevents slipping by creating a small recess in the material before full power is applied.

- Blank-fire protection system reduces damage on all wear parts by providing a cushion of oil that reduces the energy.

- Automatic lubrication system assures the breaker is constantly lubricated to improve life span on wear parts and components.

- Automatic pressure regulator ensures hydraulic breaker operation pressure, regardless of changes in outdoor temperature, delivering maximum performance across a large range of carriers.

- New for 2023 is a redesigned cradle/housing for the V32 Breaker, built for carriers from 18 to 30 tons.

Heavy-Range 2-Speed Breakers: Montabert’s 2-Speed Line of heavy hydraulic breakers is designed for use on large excavators from 20 to 80 tons in a variety of applications, from demolition to quarrying to excavating. The 2-Speed Line has many of the best features found in the premium line, but with a simpler design.

- Design simplifies maintenance, lowering costs as it also increases productivity.

- Includes patented two-speed automatic regulation, with unique detection system for the first stroke. This system offers high energy per blow on hard ground ,or high frequency on softer ground.

- Increases carrier versatility with acceptable back pressure of up to 435 psi.

Montabert, www.montabert.com

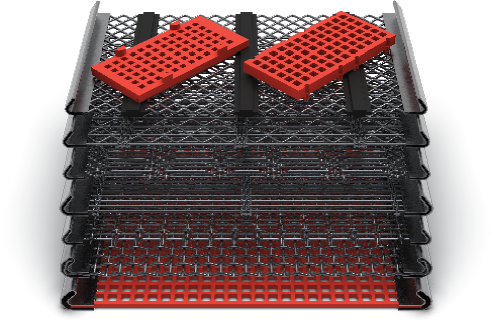

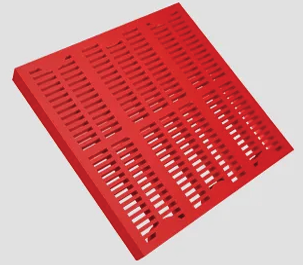

Polydeck

Polydeck, a provider of innovative modular screen media solutions, launched its latest product offerings at ConExpo-Con/Agg. The company, which has a reputation for delivering cutting-edge solutions to the mining, aggregate, energy and industrial markets, showcased RUBBERDEX ULTRAMAX and METALDEX ULTRACLEAN, designed to improve the efficiency and effectiveness of the screening process.

ULTRAMAX is Polydeck’s latest addition to its RUBBERDEX product line, and it offers up to 57.6% open area, making it an excellent alternative to conventional wire cloth. With 77.23% more open area than competitor rubber media, RUBBERDEX ULTRAMAX is designed to provide superior performance and efficiency in the screening process. The product is ideal for customers looking to increase production with an efficient and easy to install screening solution in dry sizing applications.

METALDEX ULTRACLEAN is another new product from Polydeck that extends the company’s METALDEX product line. The product offers 9.5% more open area than competitor wire panels and provides more effective cleaning, throughput, and efficiency. The product is the perfect solution for customers looking for a screening solution that provides accurate sizing while maintaining high standards of cleanliness and efficiency.

“We are excited to launch these boundary-pushing products at ConExpo-Con/Agg,” stated Trey Rollins, director of marketing. “Our goal is to provide our customers with the best possible screening solutions, and these new products are a testament to our commitment to innovation and excellence. We believe these products add to the wide range of custom solutions we can provide our customers that will improve their screening production.” Polydeck, www.polydeck/com/conexpo2023

Rokbak

Rokbak’s RA30 and RA40 haulers were on display for the first time ever at a North American tradeshow at ConExpo-Con/Agg in Las Vegas. Since rebranding as Rokbak, the Scottish company is seeing huge demand for its articulated haulers in North America, with up to 60% of the machines that leave its Motherwell factory currently heading across the Atlantic.

Rokbak used ConExpo-Con/Agg to highlight four connected product focus areas – innovation, sustainability, connected services and efficiencies – that will shape the company’s development journey and have been created from customer feedback, market research, technology advancements and product performance improvements.

The four themes encompass everything from future product developments, such as a next generation cab with higher levels of operator comfort and a modern ergonomic layout, to helping machine owners manage total cost of ownership with Rokbak’s improved Haul Track telematics system.

“We have a clear roadmap on future product development and it’s great to talk about our plans with our customers and dealers and get their feedback,” said Paul Douglas, managing director of Rokbak. “Afterall, they are the ones that guide our product strategy. It has also been nice to hear such positive feedback about our new brand, as well as the performance, reliability and color of the RA30 and RA40 haulers. For some people, it’s the first time they’ve seen the haulers in real life and their responses are incredible.”

The United States is leading articulated hauler demand with a huge infrastructure spend and a lot of construction activity around home construction and road building. The total articulated hauler market for North America is usually around 3,500 units, with 2022 closing out with an expectation-defying 4,000 units. North American customers currently account for nearly half of the total market, which was just over 9,000 units in 2022.

“Our Rokbak haulers are working in clearance, aggregates, housing, even in the energy sector,” said Robert Franklin, director of sales – Americas. “We’re seeing a lot of our machines in quarries and on infrastructure jobs, making improvements to existing roads. Then there’s a lot of other dirt work, with assistance installing power lines and putting in new roads and highways.

“We’ve had a lot of interest in our Rokbak machines out on the West Coast and then through the south, across Florida, through Georgia into Alabama territory, and up into different parts of Canada. North America is a strong, healthy market for articulated haulers, and we’ve got a good, fair share of it. Rokbak, www.rokbak.com

Sandvik

Sandvik displayed some of its newest innovations in surface drilling, rock tools, stationary crushing and screening, and parts and services at ConExpo-Con/Agg. Sandvik launched Ranger DX910i, its latest flagship top-hammer surface drill rig, together with new drilling tools. The shoulder-driven curved thread systems CT55 and CT67 increase productivity and reduce fuel consumption. The Ranger DX910i on display at ConExpo-Con/Agg was equipped with the new high-power rock drill RD930C, which expands Ranger DX910i’s hole size range beyond existing DXi rock drill options.

The company also displayed its electric concept surface drill rig, which demonstrates advanced technologies that will be featured on future Sandvik surface rigs to support more sustainable and energy-efficient drilling. It will also showcase its Leopard DI650i, a surface drill simulator and the RockPulse system for optimizing Ranger drilling results.

Sandvik also showcased its latest rock tools offerings including the Tundo RH650 down-the-hole hammer, Sandvik Alpha 340 top-hammer drilling tools, which feature an entirely new asymmetric thread, as well as LT90 top hammer drilling tools. The company highlighted its Carbide Recycling Program for recycling customers’ worn carbide tools, improving sustainability across the value chain. Sandvik Mining and Rock Solutions, www.rocktechnology.sandvik

Stedman Machine Co.

At ConExpo-Con/Agg, Stedman Machine Co. featured the company’s Grand-Slam HIS, which crushes many materials, ores, and aggregates to the proper size with one pass. The crushing action of the Grand-Slam HSI delivers properly sized material the first time through.

The Grand-Slam is available in 12 low maintenance, minimum downtime models with interchangeable breaker bars, breaker plates and side liners for all models. The efficient, front-opening design offers safe and easy access to the crushing chamber for maintenance and replacement.

Stedman Machine Co. is dedicated to treating customers like family. The company manufactures a complete line of high-quality size reduction equipment and provides professionally engineered custom solutions for material processing and handling needs that are tailored to fit your application, allowing you to concentrate on making high quality, cost-effective products. Stedman, www.stedman-machine.com

Superior Industries

Superior Industries Inc. showcased more than 250-tons of its products at ConExpo-Con/Agg. At least eight of the products were brand-new and revealed for the first time at the show.

Superior showcased:

Expanded Cone Crusher Portfolio – Two brand-new cone models were introduced and shown alongside Superior’s trusted Patriot Bushing Cone. First, the Dakota Bearing Cone, which will earn credibility for its efficient use of horsepower per ton, a straightforward lubrication system, and a wide range of liner profiles. The other new cone crusher will be called the Endeavor Spider Bushing Cone. Operationally, it’s an uncomplicated design that accepts a wide range of feed sizes with an adjustable stroke for fine tuning.

New Portable Plant Utilized in Recycling – Designed to process in recycle applications, Superior’s brand-new Portable Sentry HSI Closed Circuit Plant is equipped with a patent-pending recirculating conveyor, which centralizes the crusher feed for full utilization and extended wear life of the HSI’s blow bars. Other highlights include application-specific grizzly configurations, interchangeable cross conveyors, and screen media below the grizzly section.

New Quick to Erect Modular Wash Plant – According to Superior, its increasingly broad portfolio of Fusion Modular Platforms are a good match for aggregate producers seeking semi-static plants that are easy to install and maintain with a more economical price tag than portable plants or design-build projects. The company had a 8- x 20-ft., three-deck Guardian Horizontal Wet Screen Fusion Platform on display with an Aggredry Dewatering Screen attached to one of the discharge points.

Telescopic Stacker Builds 200,000-Ton Stockpiles – This ConExpo-Con/Agg marked the eighth time Superior displayed its famed TeleStacker Conveyor at the trade show. With radial travel, variable height and a telescopic conveyor, TeleStacker Conveyors stockpile material in a way that overcomes material segregation. This show, Superior displayed a 42-in. x 170-ft. XTP Swing Axle model with a working automation panel that visitors could interact with in the booth.

Conveyor Components to Reduce Maintenance Duties – Once again, Superior displayed a wide variety of its own conveyor components. In fact, the manufacturer showed more than three dozen individual idlers, pulleys, scrapers, and other conveyor accessories. New products included a redesigned line of Exterra Belt Cleaners with some brand-new options, a modular Load Zone Skirting System for dust and spillage control, and unique Application-Specific Idler Bearing Seals for longer-lasting idlers in demanding conditions. Superior Industries, superior-ind.com/conexpo

Watch video from their outdoor display.

Terex MPS

Terex MPS (Materials Processing Systems) launched the new Simplicity ESX “Extra Clearance” Series Horizontal Screen. The screen, along with the experienced Terex MPS team was on display at ConExpo-Con/Agg.

Russ Burns, sales director Terex MPS, said, “We [were] excited to meet with our customers and distribution partners at ConExpo-Con/Agg and thrilled to be launching this new unit at the show. It illustrates our future product road maps, which focus our efforts on offering customer solutions that are safe, reliable and provide dependable production.”

The ESX Series Horizontal 6 x 20-ft., triple-deck screen is the newest addition to the trusted range of screening solutions by Simplicity. The elliptical stroke, “Extra Clearance” ESX Series screen has taken the legendary oval stroke screen to the next level.

The increased clearance between the screen decks, compared to traditional horizontal screens, with a 23-in. wide opening between top to middle deck and a staggering 27.5-in. between the middle to bottom, provide easy maintenance access to the media. Along with upgrades to the drivetrain and suspension, ensuring this screen still has the performance that customers expect from a Simplicity screen.

The ESX Series is outfitted with the latest design techniques and advancements utilizing state of the art engineering and production processes. Engineered to improve safety and maintenance, designed to meet the most demanding applications and backed by industry leading experience. It is built stronger, runs smoother and will give customers peace of mind by providing industry leading durability. Terex MPS, www.terexmps.com