CDE, a supplier of sand and aggregate wet processing solutions for the natural processing and waste recycling sectors, announced its AGG1 product showcase and details of an upcoming talk on the topic of sustainable aggregates production.

The company, which recently announced the development of a new 250-tph sand and aggregates processing plant for All Star Sand & Gravel in Alabama, will be attending AGG1 in Nashville, March 29-31.

Alongside its product showcase, CDE Business Development Director Darren Eastwood will host a session on the topic of sustainable aggregate production at 12:30 p.m. on March 30 at the show venue, Music City Center in Nashville.

In this session, Eastwod will outline how construction materials recovered from waste can meet the market requirements when supported with the appropriate processing practices and advanced wet processing technology.

With examples of customers utilizing CDE technology, he will demonstrate how recycled sand and aggregates recovered from construction, demolition and excavation waste are suitable for high-value construction and infrastructure projects.

Commenting on CDE’s attendance at AGG1, Eastwod said: “Through our on-display equipment and upcoming talk we hope to showcase the economic and environmental benefits of CDE technology and how these innovations are being applied by sand and aggregates producers around the world to maximize their resources. We will be presenting two cutting-edge pieces of CDE technology that are fundamental to ensuring our plants deliver superior performance for our customers and demonstrate our commitment to engineering excellence.”

Equipment on display will include CDE’s patented dewatering Infinity Screen and the hard-wearing paddles from its AggMax, offering visitors the opportunity to see the inner workings of the plant up close.

CDE’s AggMax technology is engineered to operate in the toughest of conditions to maximize product yield from the most abrasive of feedstocks. Combining feeding, scrubbing, screening, and sizing on one chassis, the AggMax is suitable for a variety of material streams.

Visitors will observe the spiral alignment of its paddles, which reduces the shock of intermittent loads on the gearbox, motor and bearings. It’s this design that ensures consistent material loading and the unique paddle shape ensures maximum attrition with even the heaviest clay-bound feed material. Engineered to maximize the operational life of the plant, each paddle is highly durable and incorporates integrated wear protection plates to protect fixings.

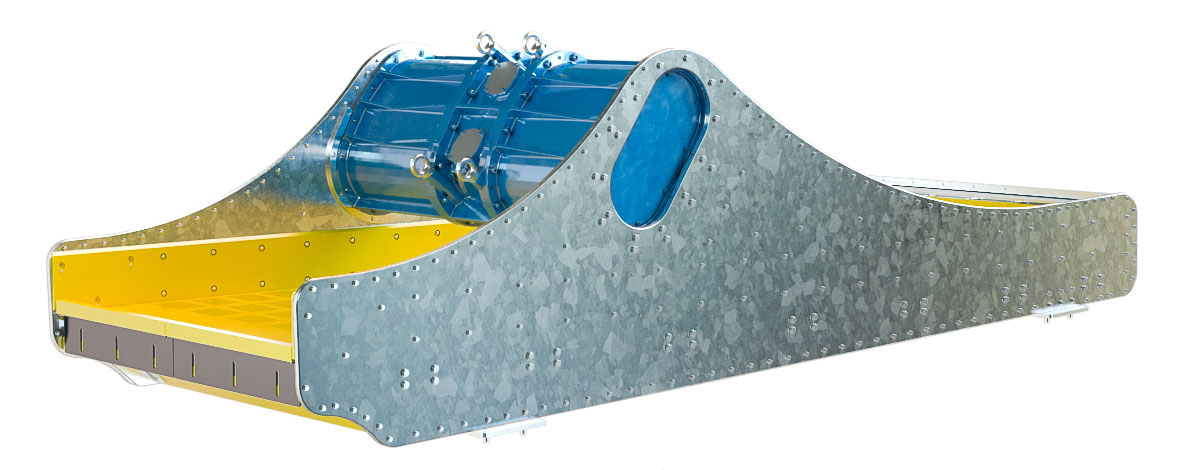

Also on display will be CDE’s Infinity Screen D1-63. CDE launched its Infinity Screen range to the market after securing a global patent for the construction of the screen sidewalls. Their bolted design includes zero welds and are galvanized as standard, resulting in a stronger but lighter screen that requires less power. These unique features make the range fundamentally different to others available on the market and serve to maximize plant life and plant availability while minimizing the time required for maintenance to enable fast return on investment.

For more information about CDE and its wet processing solutions, visit CDE at AGG1, where the team will be located at booth 1120. Alternatively, visit cdegroup.com.