Various Techniques Can Reduce Notorious Production Bottlenecks, Including High-Efficiency Screens Specifically Designed To Deter Blinding And Plugging.

By Mark S. Kuhar

In the aggregate industry, efficient screening is critical to achieve not only high production but also accurately sized product for particular applications and projects. However, two of the most common production bottlenecks – screen blinding and plugging – must be minimized to run an effective, profitable operation.

Blinding occurs when moisture causes fine, powdery particles to stick to the screening wire and harden, a process called “crusting”. Once crusting begins, it is only a matter of time before the deposits cover the screen openings and blind it, preventing efficient aggregate sorting by size.

Plugging, also called pegging, occurs when near-sized material becomes wedged in the screen’s openings and cannot be dislodged. This can severely inhibit efficient aggregate production and often leads to product contamination with excess fines in the aggregate.

Fortunately, a number of techniques can significantly reduce these production bottlenecks, including high-efficiency screens that are designed to virtually eliminate blinding and plugging.

“Certain strategies can help to reduce blinding such as changing the shaker’s stroke and increasing its speed. This can vary the shaker’s vibratory pattern, which may shake some of the particles loose and at least partially clear an opening,” said Jeff Beck, president of Hoyt Wire Cloth, a Lancaster, Pa.- based manufacturer of aggregate screen media. “Utilizing ball trays with rubber balls in pockets under the screen can also knock some particles loose as the machine vibrates and the balls strike the screen.”

Directional Angle

According to Beck, plugging can sometimes be reduced by changing the directional angle at which the aggregate contacts the screen so it is less likely to wedge in the openings. He explains that one way to achieve this is by changing any two leads on the operation’s three-phase screen motor to alter the direction of rotation.

While such strategies have the potential to lessen the effects of blinding and plugging, none really gets at the root of the problem, which is the efficiency of screen itself.

In response, screen media manufacturers have developed a number of self-cleaning screens, which are designed to improve production volume and reliability with minimal operator involvement or oversight.

One approach replaces screen woven wire bindings with polyurethane strips in an attempt to allow the wire binding to vibrate more freely in order to dislodge fine particles or wedged materials.

However, this substantially increases the cost of the screen, while doing little to allow more vibration than some field-tested, wire weave designs.

Wear Resistance

In most mild to moderately abrasive materials that are prone to blinding, such as limestone, the reputed wear resistance of polyurethane is unnecessary.

Furthermore, adding the polyurethane strip in many cases can lengthen screen replacement lead times, which can hinder production if required changeout is needed immediately.

Another more streamlined approach, utilizing woven wire binding without the polyurethane strip, can actually vibrate more freely to release such fine particles or wedged materials, with the advantage of costing up to 30% less.

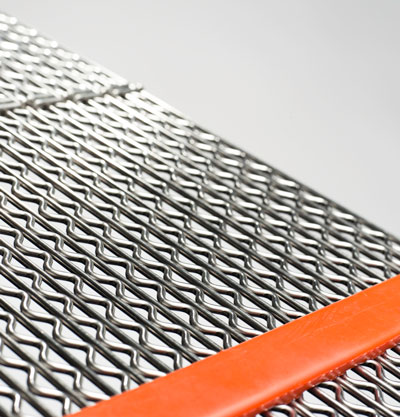

As an example of the streamlined design, the Veno Screen by Hoyt Wire Cloth is specifically engineered and designed to alleviate blinding and plugging conditions when accurate sizing is essential and the use of conventional square opening wire cloth is not acceptable.

The screen works on the principle of wire movement. It is designed with alternating pre-straightened “straight wires” and alternately crimped “sizing control” wires. Both the straight and crimped wires are alternately woven together with “binding wires”, which are placed directly over the support bars (bucker-up bars) on the vibrating screen.

In the non-blinding, non-plugging weave design, the straight wire carries a load and has a larger diameter than the crimped wire. The straight wire holds the tension. The crimped wire floats free within the wire binding, which allows more vibration.

In the case of blinding, because the larger straight wire and the smaller crimped wire are different diameters, both types of wire vibrate at different frequencies, increasing and diversifying the vibrational harmonics. This helps to break apart the crusted particles that bridge over screen openings, allowing the fine powder to effectively fall through.

Plugging

With regard to plugging, the increased vibrational harmonics also imparts wedged particles with continual micro-movement that enables most to fall through, clearing screen openings and increasing production.

In this way, the screen accurately controls material sizing, both through and over its screening surface, while staying clean and remaining efficient.

For aggregate production plants, the design has proven to last up to three times longer than other standard screens. In most mild to moderately abrasive materials, the woven wire binding offers very good wear life due to its flat, smooth design.

Since the wires are on their side with the design, there are no high points to “shave off.” So, aggregate material goes straight over it, leaving the full thickness of the wire to wear through, unlike typical square opening screens which begin to disintegrate after about 30% to 40% of the wire is abraded away.

With the Veno, another factor that lowers the cost, compared to designs with polyurethane strips, is that all the wire tends to wear evenly, extending usable life. In contrast, even if more costly polyurethane strips can last longer, the screen itself will fail when the underlying wire itself wears through.

Eliminating the polyurethane bindings in favor of such woven wire bindings also reduces lead time needed to obtain such self-cleaning screens, so aggregate plants can quickly start producing again when a changeout is unexpectedly required and there is no available stock on hand.

When aggregate plants need to enhance their productivity and minimize blinding and plugging, there are a wide range of industry strategies to accomplish this.

At the top of the list, however, should be self-cleaning screens, particularly those that are cost-efficiently streamlined to accurately size with little operator oversight, while enduring long operation in the field.

Information for this article courtesy of Hoyt Wire Cloth.