Wireless Telematics Fleet-Management System Enhances Efficiency Of Trucking And Paving Operations.

By Mark S. Kuhar

If Jess Vanderzanden could have any superpower, she’d want x-ray vision.

Vanderzanden, FleetWatcher manager for Knife River, oversees 25 trucks on jobsites that span several states. Being able to see where each vehicle is at any given time would allow her to direct vehicles around accidents and traffic slowdowns. Fortunately for Vanderzanden, she got her wish – no radioactive accident required.

With FleetWatcher, a wireless telematic system by Earthwave Technologies, she gets real time data that helps her get materials to the jobsite faster and more efficiently. She can even stagger trucks to arrive exactly when they are needed. While drivers don’t consider her a superhero, they certainly appreciate not being stuck in traffic, and she appreciates the increased efficiency and cost savings. When Jess Vanderzanden can see Knife River’s trucks’ and equipment locations in real time, everyone stays busy, everyone stays efficient, and everyone stays happy.

Knife River provides construction materials and contracting services in the western, central and southern United States, including aggregates, asphalt, concrete, paving, aggregate placement and concrete construction, among others. They saw immediate improvement after implementing FleetWatcher.

Designed specifically for heavy construction, FleetWatcher shows real-time tracking data on the trucks, pavers, and other vehicles in their fleet, allowing managers to make real-time decisions to enhance efficiency. That means that they can better route trucks, ensure a smooth flow of materials to the jobsite, and make more efficient use of trucks. This sharing of information makes coordination and communication easier, and significantly enhances efficiency of projects.

Faster Routes

Real-time tracking data recently helped Knife River determine the fastest route to deliver aggregate from its Portland facility to Vancouver. With two possible routes, GPS enabled transponders allowed Knife River personnel to see where the trucks were on the route and better direct them. Depending upon the time of day, and direction of travel, one route was more efficient than the other.

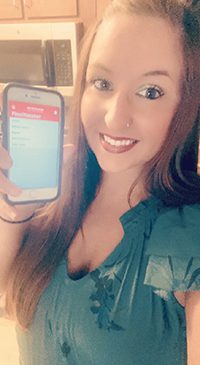

“We were able to see which was the better route because everyone had FleetWatcher installed. We were able to call the foreman and say, hey, this route seems like it’s better at this time” said Vanderzanden. “We were also able to tell the foreman how much rock he has, how many trucks are en route, how many trucks are on the scene right now waiting to dump. We were just able to have all the information at our fingertips by just logging to an app on our phone.”

With real-time tracking data, it was possible to track where trucks were and to re-route them around accidents or slowdowns, or toward routes with less congestion and freer flowing traffic.

With FleetWatcher’s Load Cycle Analysis, users can monitor not only the location of vehicles with GPS technology, but also track how long they stay there. This allows Knife River to analyze efficiency and keep track of down time and idle time. They can then improve routing and stagger trucks to reduce downtime and idle time, and prevent stoppage times at both work sites, and source sites.

Paving the Way to Efficiency

Real-time tracking can also increase efficient use of pavers. By knowing where trucks are at any given moment, users can optimize delivery loops, and with trucks making more rounds quicker, they can use fewer trucks, thus saving time and money.

Such is the case for Knife River. “Ultimately, it saved them probably $3500 on just the one day,” continued Vanderzanden. “We pulled three trucks from the job on day two after installing FleetWatcher. They were able to make faster rounds because we weren’t having trucks just sitting on the job waiting to dump. We were actually able to make better, quicker rounds in that sense.” Another example of real-time data creating real-time savings.

Having real-time tracking data available to several people allowed for better coordination between the foreman, project managers and truck dispatchers. The foreman can more efficiently direct the project, and coordinate with dispatchers to ensure that trucks arrive when they are needed. This helps to avoid slow downs and allow for adaptability to unforeseen events.

“There was an accident on one of the routes, so we were able to quickly move them to the next best route. They were tracking and seeing which routes each truck was taking and seeing which was the fastest,” said Vanderzanden. This helped Knife River improve efficiency and on time completion of projects.

The FleetWatcher system that Knife River uses can be accessed from a desktop, smartphone or tablet, which allows dispatchers and managers in offices, as well as foremen and truckers out in the field to access the information they need through whatever device they desire.

Transponders can be hardwired into company owned trucks and are installed via cigarette lighter adapter for contracted vehicles. Once Vanderzanden explained that it’s just to increase efficiency, most truckers were agreeable. “Nobody’s ever told me not to put this in their truck. I don’t think that they enjoy it fully because it’s a hassle in their minds. We pretty much tell them that this is Knife River. This is a FleetWatcher job, so if you want to work it, you need to put a FleetWatcher device in your truck. They usually are saying, okay, no problem.”

Easy to install and use across the board, FleetWatcher became a fleet-management system that quickly became a key part of daily life at Knife River.

“I started implementing this a lot more this winter during our slow times, so I have them in about ten outside haulers that haul for us consistently. Then we have all 25 of our trucks are hardwired at the sites. Once summer hits, I’ll have probably about 45 of our outside haulers having them regularly. Anytime they work for Knife River they have to turn their device on and make sure that they’re tracking on that,” said Vanderzanden.

The FleetWatcher fleet-management system provides key data that allows for more efficient use of materials and optimizes trucking, while sharing this data with key personnel simultaneously. This saves money on trucks, fuel costs, and idle time, as well as makes jobsites run efficiently. Knife River has implemented this system and seen its success firsthand.

Information for this article courtesy of Earthwave Technologies, www.EarthwaveTech.com