Optimizing Conveyor Belt Cleaner Tension to Maximize Performance and Service Life.

By Alan Highton and Todd Swinderman

Given the number of conveyor-related injuries that occur during routine maintenance and cleanup, every bulk material handler has a vested interest in technologies to help reduce hazards and prevent injuries.

Seemingly mundane tasks such as adjusting belt cleaners and removing spillage often require employees to work in close proximity to the moving conveyor, where even incidental contact can result in serious injury in a split second.

Further, spillage can contribute to the risk of fire by interfering with pulleys and idlers and by providing potential fuel. Even worse, in confined spaces, airborne particles can create the right ingredients for an explosion.

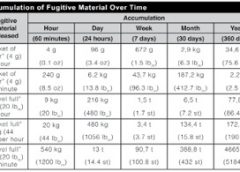

The buildup of fugitive material can occur with surprising speed. As the table below illustrates, spillage in an amount equal to just one sugar packet (about 4 grams) per hour will result in an accumulation of about 700 grams (1.5 lb.) at the end of a week.

If the rate of escape is 4 grams per minute, the accumulation will be more than 45 kg (nearly 100 lb.) per week, or more than two tons per year. If the spillage amounts to just one shovelful per hour (not an uncommon occurrence in some operations), personnel can expect to have to deal with more than 225 kg (nearly 500 lb.) of fugitive material every day.

|

|

| Table 1: Material loss from conveyors. |

Belt Cleaning to Reduce Carryback

Although there are a number of belt cleaning technologies available to conveyor operators, most designs in use today are blade-type units of some kind, using a urethane or metal-tipped scraper to remove material from the belt’s surface.

These devices typically require an energy source – such as a spring, a compressed air reservoir or a twisted elastomeric element – to hold the cleaning edge against the belt. Because the blade directly contacts the belt, it is subject to abrasive wear and must be regularly adjusted and periodically replaced to maintain effective cleaning performance.

Typically, the blades of a cleaner do not cover the full width of the belt, because the full belt surface is not generally used to carry material. CEMA specifies the minimum blade coverage based on belt width, as shown in Table 2.

|

| Table 2: CEMA minimum blade coverage based on belt width. |

|

| Figure 1: When the blade is wider than the material flow, its center may wear quicker than the outer edges. |

|

| Figure 2: As the center of the blade wears unevenly, the outer edges create an effect called a “smiley face” or “mooning.” |

Various belt cleaner suppliers have their own standards for blade width. Some manufacturers opt for more than the minimum coverage, but rarely does the blade size need to be equal to or greater than the belt width. For optimum cleaning, the dirty portion of the belt’s carrying surface should be observed or calculated and the cleaner’s size matched to it.

Installing a blade that is wider than the material load on the belt can lead to undesirable wear patterns. The center section of the blade may wear faster than the portion of the blade on the outside area of the belt, because there is more abrasive cargo in the middle.

The outside portion of the cleaning blade will then hold the center section of the blade away from the belt. As a result, carryback can flow between the belt and the worn area of the blade, accelerating wear on this center section. Eventually, the process creates a curved wear pattern sometimes referred to as a “smiley face” or “mooning.”

Tensioning

The ability to maintain the proper force required to keep the blade edge against the belt is a key factor in the performance of any cleaning system. Blade-to-belt pressure must be controlled to achieve optimal cleaning with a minimal rate of blade wear.

There is a popular misconception that the harder the cleaner is pressing against the belt, the better it will clean. But research has shown that there is actually an optimum range of blade pressure, which will most effectively remove carryback material. Increasing tension beyond this range raises blade-to-belt friction, thus shortening blade life, increasing belt wear and increasing power consumption – without improving cleaning performance.

Too much pressure can prevent proper contact, forcing the tip away from belt and leaving a small gap that can lead to hydroplaning. Material will wedge between the blade tip and belt, potentially leading to premature wear of both the blade and belt.

|

| Figure 3: Linear and radial belt tensioning. |

Operating a belt cleaner below the optimum pressure range delivers less effective cleaning and can actually accelerate blade wear. A belt cleaner barely touching the belt may appear to be in working order from a distance, whereas in reality, excessive amounts of carryback are being forced between the blade and the belt at high velocity.

This passage of material between the belt and the blade creates channels of uneven wear on the face of the cleaner. As material continues to pass between the blade and the belt, these channels increase in size, rapidly wearing the blade to a jagged edge.

Another common source of blade wear that often goes unnoticed – even with a properly installed and adjusted cleaner – is running the belt empty for long periods of time. Even though the cargo may be abrasive, it often has moisture in it that serves as a lubricant and coolant. Small particles embedded in the empty belt’s surface can be as much as 60 g/m2 creating a kind of sand paper. In effect, running the belt when empty results in a doubling of the wear rate of both the blade and the belt.

There is actually quite a complex geometrical relationship between the tensioner’s spring force and the blade geometry during its wear life, in order to achieve the most effective cleaning pressure.

Most tensioners are designed to be a compromise between optimal pressure at a single point of wear and acceptable pressure over the entire wear profile. In spring tensioners (such as twist or coil types), there is the additional complication of the spring force decreasing as the blade wears, bringing one more variable to the equation. So designers are trying to optimize four factors: decreasing spring force, changing blade geometry, blade width and blade type.

As urethane cleaner blades wear, the surface area of the blade touching the belt increases. This causes a reduction in blade-to-belt pressure and a corresponding decline in cleaner efficiency. Therefore, most mechanically tensioned systems require periodic adjustment (re-tensioning) to deliver the consistent pressure needed for effective carryback removal.

There are competing theories on belt cleaner tensioning. Linear-tensioned cleaners are pushed up (in a line) against the belt, and radially tensioned cleaners are installed with a mainframe as an axis and rotated into position. In addition, some hybrid systems incorporate vertical tensioning with a radial relief mechanism.

Linear-adjusted cleaners generally require access to both sides to provide balanced pressure. Because of this, the tensioners for these cleaners often have some form of powered adjustment that can be remotely controlled. Linear tensioners maintain a constant cleaning angle as the blade wears and can usually be designed to allow easy withdrawal of the cleaner for maintenance without removing the tensioner.

Radial-adjusted cleaners have several practical advantages over linear designs. They are easier to install and can more readily rotate away from the belt to absorb the shock inherent in belt motion and splice passage.

To overcome the problem of the blade angle changing as the blade wears, a radial-adjusted belt cleaner can be designed with a specially engineered curved blade, known as “CARP” for Constant Angle Radial Pressure. With this innovative design, the changes in contact angle and surface area are minimized as the blade wears, helping to maintain its effectiveness throughout the cleaner’s service life.

Air Tensioning

|

| Figure 4: Constant Cleaning angle and Pressure. |

Mechanical tensioner designs work well as long as they are properly adjusted, but in most cases this requires periodic attention from maintenance crews as the cleaning blade wears down. In addition, some operators will loosen a mechanical tensioner to reduce drag at start-up, which reduces the cleaner’s performance if it’s not correctly re-adjusted afterward.

In contrast, pneumatic tensioners have some advantages vs. mechanical construction.

The air tensioner keeps the blade in contact with the belt. For linear adjustment the air tensioner maintains a constant force on the blade that results in a constant cleaning pressure. However, with radial tensioning the pressure must be reduced as the blade wears to keep constant cleaning pressure.

For sites without available electricity, systems are available that can actually be engineered to generate their own power from the moving conveyor belt, creating the energy to run a small compressor and store the pressurized air in a reservoir tank to maintain constant blade tension.

One automated pneumatic tensioning system engineered for belt cleaner applications is now delivering precise monitoring and tensioning throughout all stages of blade life, extending the effective service life of both the cleaner and the belt.

Also equipped with sensors to confirm that the belt is loaded and running, the system automatically backs the blade away during stoppages or when the conveyor is running empty, minimizing unnecessary wear to both the belt and cleaner.

The result is consistently correct blade tension, with reduced power demand on start-up, all managed without operator intervention. Automatically tensioning cleaners also delivers a significant savings in labor hours, allowing personnel to concentrate on core business activities.

|

| Figure 5: Automatic cleaner tensioning uses pneumatic power to maintain correct, consistent blade pressure. |

Installation

A critical ingredient in the performance of any belt-cleaning system is its installation. Improper installation will have an adverse effect on how well the cleaner works, reducing both blade life and cleaning efficiency. Most performance problems with belt cleaner systems are due to improper installation, lack of maintenance or both.

Considerations affecting the installation position of a belt cleaner include:

- Cleaner design.

- Tensioner and mounting requirements.

- Bolting or welding the cleaner in place.

- Installation on chute wall or hung from stringer.

- Position of cleaner to avoid conveyor structural beams, bearings and drives.

- Support for the cleaner.

- Access for maintenance.

|

| Figure 6: Sensors are used to back the blade away during stoppages or when running empty. |

Inspection

Since many cleaners die a slow death due to lack of informed maintenance, access for inspection, cleaning and service is critical. After startup it may be impossible to correct for access and location problems.

Nobody wants to lay on a pile of grease or spillage to try to get a peek at a cleaner buried in an inaccessible location, but this is often the case when attention to these details are missing in the original design. Proper location of the work platform to allow mounting cleaners in a preferred location and providing for ergonomic maintenance will greatly improve the chances that the cleaner will be inspected frequently.

Maintenance

Even the best designed and most efficient of mechanical belt cleaning systems require periodic maintenance and/or adjustment, or performance will deteriorate over time. Proper tensioning of belt-cleaning systems minimizes wear on the belt and cleaner blades, helping to prevent damage and ensure efficient cleaning action.

Belt cleaners must be engineered for durability and simple maintenance, and conveyors should be designed to enable easy service, including required clearances for access. Service chores that are straightforward and “worker-friendly” are more likely to be performed on a consistent basis.

|

| Figure 7: Ease of service should be a key element in any belt cleaner tensioning system. |

Elements that can be incorporated into a conveyor belt cleaning system to improve maintenance procedures include:

- Adequate service access with ample clearances, as recommended by CEMA.

- Access windows with easy-to-operate doors installed on both sides of the pulley, in line with the axis of the belt cleaners.

- Cleaning elements that slide out for service, without requiring mainframe removal.

- Components including blades and mainframe that resist corrosion and abuse.

- Components that allow quick performance of required adjustment and service with simple hand tools.

- Automated load sensing and blade tensioning.

In one survey of factory maintenance technicians, respondents estimated that only about 20 percent of all conveyors have the proper cleaning systems and of those, just 20-25 percent are well maintained!

The problem is that most in-house inspections never happen, and when they do occur, they tend to be casual reviews by people who are not highly trained in what to look for or how to maintain the cleaners. Most managers will feel this is a simple task, which should be done in-house; the truth is that cleaner maintenance is rarely a priority, reinforcing the benefits of automated tensioning.

Some equipment manufacturers offer factory-direct service from professionals who are aware of the hazards, have the appropriate tools and are trained in safe and proper service, while reducing the workload on customer personnel and improving cleaning performance.

The use of factory-trained and certified specialty contractors can also help ensure that belt cleaner maintenance is done properly, and on an appropriate schedule. Further, experienced service technicians often notice other developing system or component problems that can be avoided if they are addressed before a catastrophic failure occurs, helping conveyor operators avoid potential equipment damaging and expensive unplanned downtime.

By setting the cleaning goal necessary for each individual operation and purchasing a system adequate for those conditions as laid out in CEMA standards, it’s possible to achieve carryback control and yet obtain long life from belt cleaners. The bottom line is that properly-installed and adjusted belt cleaners help minimize carryback and spillage, reducing risk and overall operating costs.

Alan Highton is national sales manager and Todd Swinderman, is the retired president and CEO, of Martin Engineering.