Depending on the application, a crusher is either at the heart of the process or is a vital part of the process. It simply cannot be removed for extended periods of time without affecting the productivity. If major components start to fail and the crusher begins nearing the end of its life, Sandvik can replace it and restore the entire crushing system to its original glory.

The Sandvik Reborn solution rebuilds a crusher system by exchanging the existing crusher for a new one, and reutilizing existing crusher auxiliaries. This cost-effective solution is up to 40 percent cheaper than replacing the entire crusher system, and is fully compatible with existing plant infrastructure. It also minimizes the risk of unplanned downtime that can come with a major overhaul.

“Our Sandvik Reborn solution is a quick and cost-effective way to replace a customer’s worn out crusher with a new one and reuse all of the existing infrastructure,” said Andreas Christoffersson, product manager – rebuilds and upgrades, Sandvik Mining and Rock Technology. “The new crusher is also backed by our three-year extended warranty, and includes on-site services to help customers maximize productivity.”

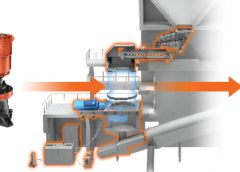

If the auxiliaries meet preconditions for durability and quality, Sandvik can provide a solution to replace the customers’ existing Sandvik crusher. Reutilizing existing crusher auxiliaries usually includes the motor, lubrication and hydraulic tank, hoses, coolers, automation system, sub-frame, electrical cabinets and wiring. As part of the program, the customer will trade in their old crusher.

The footprint of the new crusher is identical to the old one, so there is no need to redo any civil or electrical engineering work or alter the feeder and conveyor arrangements. Sandvik Reborn is an efficient ”plug and play” installation that minimizes disruption and maximizes productivity.

A certified Sandvik technician will be on site to supervise the installation of the new crusher to guarantee it is done quickly, thoroughly and efficiently. The customer also gets training in how to best use and maintain the new crusher, as well as condition inspections after the installation that offer maintenance recommendations and alerts about worn-down parts they need to order.