An Aggregates Plant is a Perfect Environment for a Drum Motor. But Why is the Drum Motor a Better Solution than an Exposed Drive?

By Mark S. Kuhar

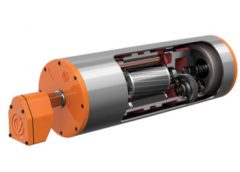

A drum motor is a one-component conveyor drive where the motor, gear drive and all moving parts are enclosed inside the drum. The motor and gears operate in an oil bath ensuring proper lubrication and cooling. With no external motor, gear reducer, sprockets, chain or OSHA required chain guard, no external component maintenance is required. We asked Heavy Industry Drive Specialist Matthew Lepp at Van der Graaf to talk a little bit about the product.

What makes a drum motor special? Why is a drum motor superior to other types of motors?

|

| The compact design allows the units to work well in tight environments typically found in mobile equipment. |

The drum motor provides a number of features that are not typically found in conventional drive systems. By eliminating external components, a drum motor reduces the footprint of a conveyor drive, saving space. The reduction of components also results in a reduction of guarding requirements, making the drum motor a safer solution. With no external wear parts, a Van der Graaf drum motor requires only an oil change every 50,000 hours. Combined with an electrical savings of up to 30 percent, a drum motor provides a lower total cost of ownership compared to a conventional conveyor drive.

How is the manufacturing process for drum motors unique? How does Van der Graaf’s manufacturing capability contribute to making its drum motors a successful product?

Stringent quality control procedures are followed; testing every unit for a number of operating factors at several points through the process, including stator performance, sealing systems pressure tests, as well as noise and vibration confirmations. All electric motors are wound in-house, including a vacuum pressure impregnation or VPI, of every stator to optimize their design for variable frequency drive use as well as in high-vibration environments. Van der Graaf is the only drum motor manufacturer to use this stator life-extending process on every motor manufactured.

Why is an aggregates plant environment perfect for use of a drum motor?

|

| Van der Graaf is the only drum motor manufacturer to implement a life-extending Vacuum Pressure Impregnation (VPI) process on every motor manufactured. |

|

| Stringent quality control procedures are followed. |

Drum motors offer a number of benefits to aggregate plants. The compact design allows the units to work well in tight environments typically found in mobile equipment. With virtually zero maintenance, they can be used in hard to access places like stackers and elevated conveyors, without the need to regularly access them for bearing greasing or v-belt tensioning. Using mechanical sealing systems, we’re able to operate continuously in wet, dusty environments. With no contamination of internal parts, this contributes to a longer drive life. Our heavy-duty internal components are able to withstand the constant vibration and shock loading of an aggregate application with no additional gear or bearing wear.

Can a drum motor be easily retrofitted into the production process?

Typically installation requires four bolts for the mounting brackets and an electrical connection to the motor. The drum motor eliminates conventional motor and gearbox support brackets, torque arms and most guarding. This facilitates retrofitting into the production process with minimal downtime and cost.

What maintenance can I expect on a drum motor?

Maintenance requirements for a drum motor are virtually zero. All of the components; electric motor, gearbox and bearings, are enclosed within the drive shell and bathed in oil, providing continuous lubrication. The only required maintenance is an oil change every 50,000 hours of operation. A Van der Graaf drum motor eliminates the regular maintenance schedule typical of a conventional motor/gearbox drive.

Can using drum motors contribute to safety at my operation?

By utilizing a drum motor, external guarding for v-belts, chains, couplers and rotating shafts are eliminated. The drum motor design reduces potential problematic areas per OSHA and MSHA safety requirements – pinch-points and guarding.

What kind of energy savings might I realize by switching to drum motors?

Drum motors have shown up to 30 percent energy savings compared to a conventional conveyor drive system. This is accomplished by eliminating energy-robbing components such as right-angle gearboxes, v-belts, chain drives and couplers. Van der Graaf utilizes a high-efficiency electric motor coupled with an in-line gearbox, resulting in a higher overall efficiency, and improved cost savings.

What is the life of a drum motor?

|

| Quality control is achieved through consistent R&D, combined with the latest automation in manufacturing equipment. |

Van der Graaf standard design components are designed for 80,000 hours, depending on the application and loading. The 80,000-hour interval can be exceeded, the average life we’ve seen in the field is 20 years.

How long has Van der Graaf been in the manufacturing business? What is the company’s history?

For 69 years, Van der Graaf has been manufacturing and supplying equipment to the power transmission industry for conveyor applications. Van der Graaf started in 1948 in Vollenhove, Holland, with North American manufacturing starting in 1985. Today, Van der Graaf has more than 200,000 sq. ft. of manufacturing space in the United States and Canada.