By Brian Barlow

| The solution? A hydraulic clamp rail system. |

In early 2009, I received a fascinating telephone call from a long-time screen media salesperson for a manufacturer with whom I had worked closely as an outside resource for several years. Mark Roppo was calling to ask in confidence if he could share a project with me that he had been working on for a few years with an engineer who happened to be a full-time racecar builder for guys who like to race on the weekends. His name was Randy Parker.

Naturally, I was curious. As owner of a sales development and marketing firm, working with manufacturers in the construction, aggregate, recycle and mining equipment markets for years, as well as a former co-owner of an industry-related parts company and an independent equipment sales company, how could I not be?

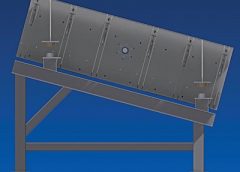

Mark explained to me that he and Randy had spent a few years pioneering a solution to one of aggregate and mining’s most dreaded jobs – and a primary contributor to both workman’s compensation claims and downtime within the industry – screen media change-outs. They had developed and applied for a U.S. application and method patent. They had built a demo version of a partial screen, and had shot a video to demonstrate their solution – a hydraulic clamp rail system. They were serious. I saw that it could work. All of the components and hydraulic actuator design are similarly used in other construction equipment, working in very tough, demanding applications.

Once I realized what the system would do, how much it could save in screen changing downtime and all of its other benefits, I jumped on board. They needed someone who knew the industry well, could immediately see the future impact on screening and production, could package it well and had the relationships to take it to the manufacturers and sell it. A legal search also proved there were no similar existing solutions. So we formed Advanced Screening Solutions Inc., and stepped out into the industry.

|

| The hydraulic clamp rail system could siginificantly impact screening production for producers and miners in short order. |

Hydraulic Clamp Rail System

Our hydraulic clamp rail system could significantly impact screening production for producers and miners in short order. It could reduce change-out time for worn-out, hooked screen media by about 50 percent from the typical 8-to-12 hours for a 3-deck, 8- x 20-ft. screen.

Instead of physically loosening or removing the numerous bolts or wedges holding as many as four to five clamp rails that are typically 4 ft. in length on both sides of each screen deck, the plant operator could push one or more buttons connected by hydraulic hoses to actuators on one or more decks or sections. This would open up the clamp rails and allow the old screen media to be removed and replaced. Pressing the button again would close all of the clamp rails simultaneously, and both apply and maintain an even tension, eliminating a common cause of screen media breakage.

While Mark, Randy and I were waiting on the lengthy patent approval process, we began to approach potential manufacturers about buying the technology. We had calculated the benefits and payback to the users well. We figured they could justify the added cost of our clamp rail system to a new screen box and be amazed. Turns out, we were a bit ambitious about how fast and at what price we would sell the hydraulic clamp rail system.

We did receive an immediate offer from a manufacturer to engineer and build it, and we would be paid a royalty on each box sold. This manufacturer built quality screens, but lacked volume. We declined. We tried a sort of bidding war among three industry majors. There was interest at several levels within two of the three manufacturers, but ultimately we failed.

|

| The key is opening up the clamp rails. |

We then expanded our opportunity to every screen manufacturer – from the global players to the smaller, more focused manufacturers. And we saw interest, but no commitment. We pitched it heavily at the AGG1 show in 2010 and ConExpo-Con/Agg in 2011. And we were especially confident about achieving success after being awarded a patent in 2011 – but no luck.

Always, we saw interest from the product development and field-sales level people, but not from those who had the authority to make it happen; or those in authority showed interest, but their engineering departments were already committed for months to years.

I began to notice people in the aisles at tradeshows would quickly walk in another direction or share only a polite nod. Responses to my telephone calls slowed down dramatically. As partners, Mark, Randy and I had devoted countless hours developing and patenting the product, and countless more hours as I pitched it over and over again.

Door Opens

Then, as discouragement really began to take hold, an industry colleague who had begun working for a smaller screen manufacturer with two legendary screen brand names brought me into his employer, Smico/Symons, for a meeting with its two owners – both fascinating people in their own rights.

Randall Stoner and his partner Erick Heald took a quick look at the patent drawings and said yes, they could see it working. They would engineer it, build a screen, test it in their screen-testing lab and bring a working 4- x 8-ft., two-deck model to ConExpo-Con/Agg 2014 in Las Vegas.

Their stipulation was we had to agree to no money down and no firm purchase agreement. We all agreed, however, to review our relationship going forward after we experienced the feedback and level of interest from aggregate and mineral producers and recyclers at the world’s second largest equipment show.

We took the deal. We knew we could rely on what screen users had said to us all along: It’s a great idea and they would pay a premium for this type of screen. Look for a full report after ConExpo-Con/Agg.

Brian Barlow is president/CEO of Barlow Strategic Sales & Marketing.