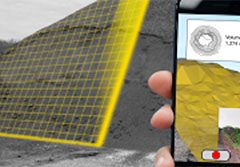

Stockpile Reports (SR) is launching an upgrade for its inventory measurement system. Companies are used to waiting several hours, or even days, to get measurement results for their stockpiled inventory. Now, they can generate inventory-level reports instantly with the SR iPhone app. Companies will receive the report immediately, simply by doing a quick perimeter walk of the stockpile with their iPhone.

The real-time measurement capability is an industry first and represents a significant evolutionary step forward. “We’ve been developing the instant measurement technology for a while now. It’s been a primary objective to bring the ability to measure stockpiles in real-time with the iPhone to our supply chain customers – and it’s finally happening. We believe life is real-time and business should be too. We are all set to launch the beta program this year, and start offering the solution to everyone come 2021.”

Besides the iPhone app, the SR Automated Measurement (fixed cameras) system also supports instant, real-time measurements. For supply chain customers, this is a revolutionary solution. Customers with cameras fixed on their stockpiles are able to get auto-generated reports, never running short on inventory.

Measuring your inventory has never been so effortless. It’s as automated as it gets – you’ll be able to assess your stockpile automatically without lifting a finger. SR is the only vendor on the planet that supports supply chain automation. Customers who sign up will gain a leg up on the competition.

In industries where time is money and inventory levels drive business decisions, knowing where your materials are at every point in the supply chain is a bona fide game-changer. Simply put, it makes the impossible possible.

You can monitor every pile at any site anywhere in the world at any time. You can gain crucial data remotely while you’re working from your office or job site. All you need is an employee with an iPhone in hand to walk around the stockpile (or a pair of fixed-cameras for completely autonomous measurement).

You can accurately measure the production rate with SR’s system at any time. You don’t need to wait until the end of the day, until after the production cycle ends. You can calculate how much you’re producing per hour instantly – and make changes on-the-fly as needed.

Production planning doesn’t have to involve guesswork anymore:

- Optimize your asset logistics. You’ll have the power to have your dispatch teams make important decisions around when and where to send trucks.

- Know if you can produce the order. Do you have enough materials to produce the order? You don’t have to make an educated guess. You can use reliable, actionable data instead.

- View the projection capacity. How much does a unit at your job site produce every hour? What’s the exact loadout capacity?

- Figure out the transportation capacity. How much capacity do you have to accept a new delivery of additional materials? Do you have enough space? You will get a clear and accurate number so that when you order, you have adequate space.

- Find the best location to complete orders. Have a pending order? Find out which site currently has the capacity to hold the materials until it’s shipped off.

- Optimize your asset logistics. You’ll have the power to have your dispatch teams make important decisions around when and where to send trucks.

Delivery Verification

You can reliably assess incoming deliveries. When an order is coming in, you can have it delivered to a specific location. After the point of delivery, the driver or other employees can take an instant measurement of the pile with our iPhone app. In a few seconds, you’ll know if you got what you ordered. It’s an instant, verified delivery.

Forecasting – Is There Enough Space?

Space is always a constraint. You can stay on top of all the space you have across all your job sites with instant, immediate measurements. Some locations you can measure include barges, ships, depots, warehouses, and terminals.

Manage High Turn Inventories

Do you own “tight footprint” plants? These are plants with high production and limited storage. It’s a constant battle to keep it all balanced and running smoothly. SR’s new upgrade will make it much easier to manage your high turn inventory.

Improve Existing Systems

You can integrate SR’s system with any other logistics and management systems you presently use and improve their efficiency. Also, if you use SR’s iPhone app, you won’t need a belt scale for measurements, which is cumbersome and time-consuming. You also won’t need to pay astronomical belt-scale calibration fees. Companies with 20 belt scales could be looking at up to a quarter of a million dollars in calibration fees annually.

How Do You Receive the Instant-Measurement Upgrade?

The instant inventory measurement upgrade will be launched for everyone in 2021. SR will make an announcement when it happens. A beta version is in the pipeline – They plan to release it by the fourth quarter of 2020. At the moment, an early-adopter program is available for some of the SR’s logistics customers.

Stockpile Reports, www.stockpilereports.com